What is Vacuum casting?

What is Vacuum casting?

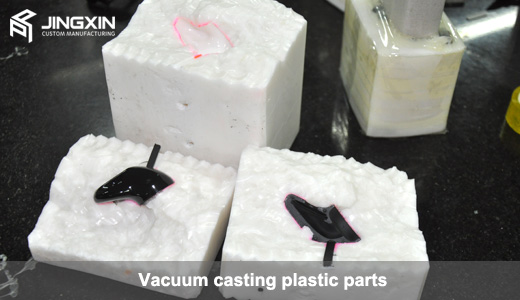

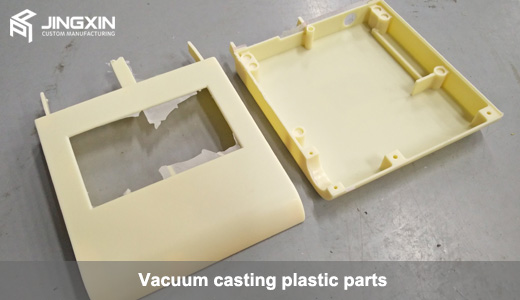

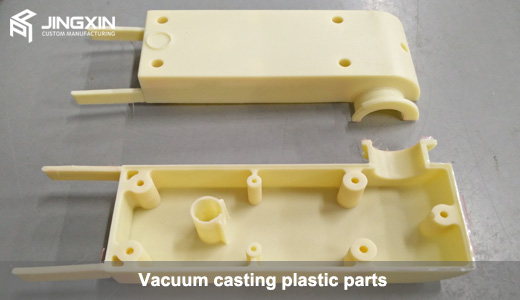

Vacuum Casting is a copying technique used for the production of small series of functional plastic parts. Using two-component polyurethanes and silicone molds, Vacuum Casting is known for its fast production of high-quality prototypes or end-use products.

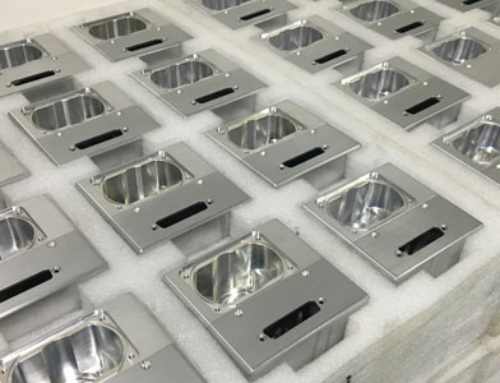

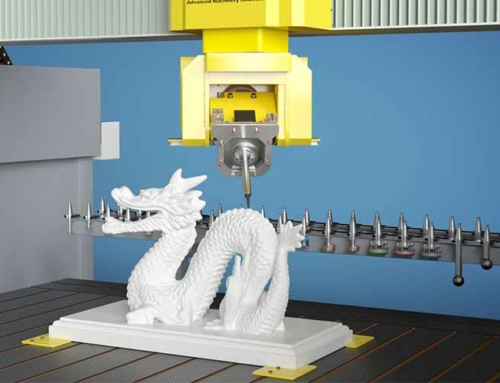

Firstly, using SLA 3d printing or CNC machining building a master model with the high quality surface finish. Then make a silicone model by casting silicone around the master copy under vacuum to avoid air bubbles. The silicone mold is cut according to designed parting line, take out the master, leaving a cavity to make the copies.

Vacuum casting Advantage

- Fast lead time

- Low tooling cost

- High surface finish 125-150 RMS

- Best solution for short run production & pre-production

- Wide range of polyurethane resins

- Various kinds of inserts possible

- Over molding, two or three kinds different color or plastic, soft or rigid.

- This makes vacuum casted models especially suitable for fit and function testing, marketing purposes or a series of final parts in limited quantities.

Technical Specifications for Vacuum Casting

- zero degree draft;

- wall thicknesses of 0.5-1.0mm

- tight tolerances;+/-0.3mm

- unlimited pattern life; when pattern changes are required they are easy to alter at a low cost.

Materials for Vacuum Casting

Polyurethanes are similar to rubber, PP, ABS, and PC. These materials provide an outstanding variety of properties and offer the possibility to match colors and cast transparent components. Learn more

JINGXIN is a large one stop custom manufacturing factory in China, we offer rapid manufacturing service and short run production, supplying the parts with a cost completive and time-saving. Send us your CAD files today to get a free project review and get a quote.or contact us directly enquiry@jpmcnc.com