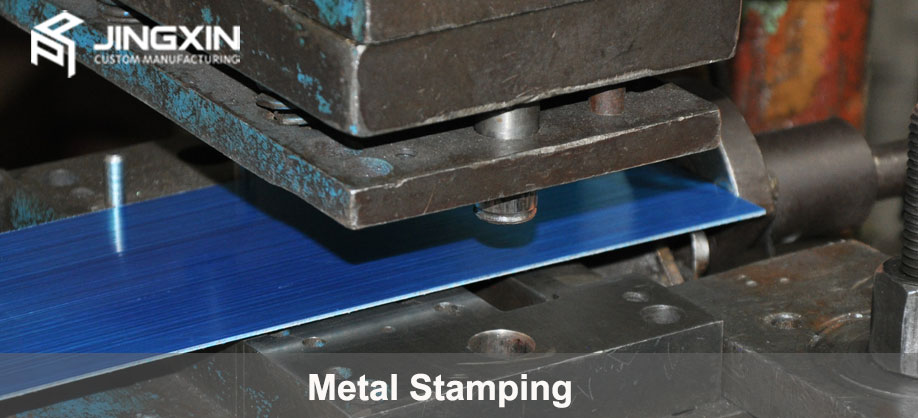

What is Sheet Metal Stamping?

Metal stamping is a kind of Metal forming process. Its characteristic of high pressures between two contacting surfaces with a custom die mold according to the parts design. It is cold forming operations.

Single stage die

Every dies is only used to make one feature of the parts, low cost of die. Especially suitable to low volume production and for big size parts.

Compound Die stamping

Compared to single stage die, compound dies allow two or more features or operations to be combined into one die. This is a cost-effective method for high volume metal stamping parts and keep labor cost and stamping tools cost low.

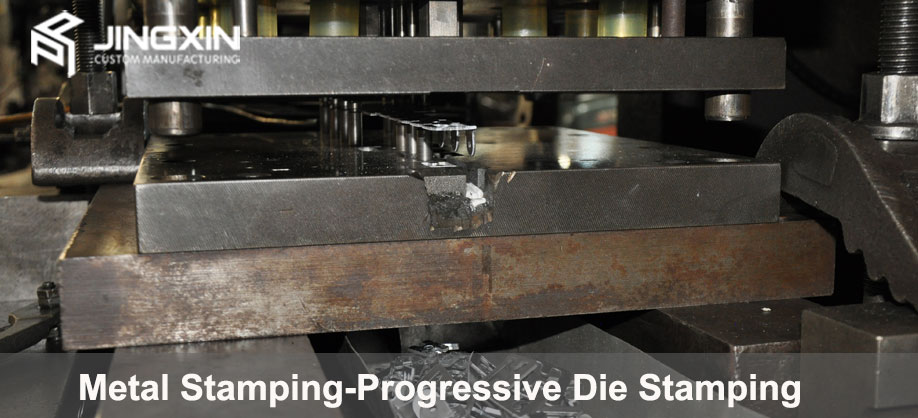

Progressive Die Stamping

This process consists of many individual stroke. Each stroke performs different operations on the part which is carried smoothly in the tooling from one stroke to another station. By the scrap strip and is cut off from the scrap strip in the final stroke. Progressive die stamping is suitable high volume production of small or middle-sized parts ,High production efficiency, low cost.

Progressive Die Stamping-sheet metal stamping

Shearing: Shearing is the cutting of the work piece, this would include punching holes.

Bending: Bending involves the deformation of the work by way of bending about a certain axis.

Deep Drawing: Deep drawing is a metal forming process. In which a flat piece of plate or sheet is forced into a die cavity to take a shape, such as a cup.

Deep drawing -sheet metal stamping

More about sheet metal stamping process please refer to JINGXIN website

If you have any queries to metal stamping please feel free to contact us or send email to JINGXIN experts to help you out.