![]()

Silicone Mold Vacuum Casting & Rapid tooling for short-run molded plastic parts, The best RP mothed with low cost for rapid manufacturing.

Vacuum casting provides End-use, rigid or flexible plastic parts with production-level quality. Built without expensive and time-consuming hard tooling, vacuum casting is the Ideal process for rigid or soft plastic parts with short-run production & pre-production

At JINGXIN® precision machinery Ltd., has the solution to uses a 3D printer or CNC machined master pattern and silicone molds to provide high-quality vacuum casting plastic parts and over molded parts with soft TPU or rubber. The Maximum size is up to 1200mm long.The general Shrinkage rate of + 0.15% is expected.We have done 1200+ parts for industrial use such as medical device housing, Automotive parts enclosure, Household appliance.etc.

For more details and new project inquiring, Welcome to Contact our Project manager directly (Mr. Sammy: sammy@jpmcnc.com)

JINGXIN Advantages to be used for Custom rapid manufacturing services

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Fast Lead time

JINGXIN skilled machinists produce high-quality parts as little as 3-6 working days

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

High precision

tolerances ranging from +/-0.1mm – 0.2mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

General introduction: Manufacturing steps of Vacuum casting

∨ More Tips you may like

→What is 3D printing? How does a 3d printer work?

Vacuum casting process is used for:

Vacuum Casting VS SLA 3D printing

| Advantage | Vacuum casting | SLA 3D printing | ||

|---|---|---|---|---|

| Raw material | Rigid or soft plastic | VS | Photopolymer | |

| Application | End-use, function testing, promotion | Outlooking checking, and design evaluate | ||

| Physical characteristics | |

Tougher than SLA printed parts | Less Strength and rigid |

Vacuum casting VS Rapid hard(aluminum or steel) tooling

| Advantage | Vacuum casting | Rapid hard tooling | ||

|---|---|---|---|---|

| Tooling Cost | 1/10 cost of rapid hard tooling | VS | expensive | |

| Lead times | 1 week | 3 weeks at least |

What kind of material is used for Vacuum casting process?

| No. | The Material used for vacuum casting manufacturing Methods |

|---|---|

| 01 | PU |

| 02 | transparent PU |

| 03 | soft share (A-D) PU |

| 04 | PC |

| 05 | POM |

| 06 | ABS |

| 07 | PP |

| 08 | Other special plastic |

| Vacuum casting material data sheet download here | |

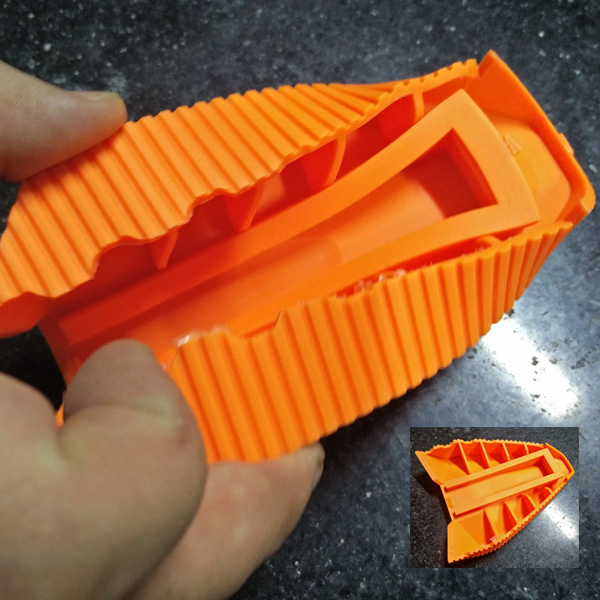

Vacuum casting Examples

Transparent PC parts for ATM

Soft PU parts for commercial products

Medical ABS enclosure

The Custom manufacturing Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.