Sheet Metal Forming

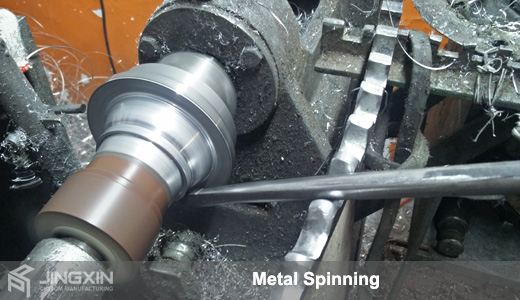

Sheet metal forming, At JINGXIN® precision machinery Ltd., offering Sheet Metal forming fabrication services including metal stamping, Deep drawing, metal spinning, and CNC bending services with many kinds of metal material for 10000+ production.

At Jingxin, Our team can handle your entire project from initial design and rapid prototyping to rapid production, quality control and post-production (short-run production) checks and mass production. We provide a true one-stop solution to your metal stamping requirements. With over 20 years in business, we are contracted as a supplier with Volove automotive in Sweeden

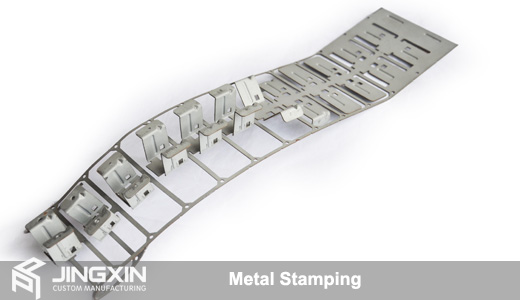

Precision Metal Stampings

We understand that our customers need exceptional products that are consistent with quality, design and build specification. Our company has invested heavily in advanced stamping, bending, deep drawing equipment, enabling us to quickly deliver components in the volume you need. We have a rapid response team (one sales person and engineer as a group) in place, whose role is to ensure that your order is completed on time and give your our advice in terms of your design has some issues in mass production before mold and tooling making, save you time and cost for tooling modification.

To find out more about our services or discuss your project in more detail.Welcome to Contact our Project manager(Mr. Sammy : sammy@pmcnc.com) directly for your project.

Our Capabilities in Sheet Metal Forming

| Items | capabilities |

|---|---|

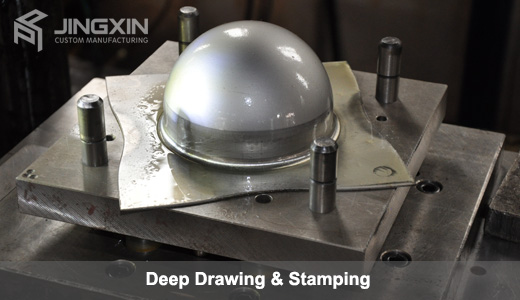

| Services | Full range of service:metal stamping,deep drawn stamping ,and forming service |

| We focus on | Auto parts, Medical,lighting fixture, Home appliance |

| Proudction volume | Short Run or 10000+ production, and high volume production |

| Maximum parts size | 1500 mm length x1000 mm Width |

| Material thickness ranges | from 0.2mm to 10mm |

| Typical tolerance range | from +/- 0.05mm-0.2mm |

| Tooling lead time | 20-25 working days |

Equipment list for sheet metal forming

Automatic high-speed presses and feed lines & Single punching Hand fed operations

| No. | Sets | Model | Brand | Year |

|---|---|---|---|---|

| 01 | 2 | 400T Hydraulic Press | SWD (China) | 2012 |

| 02 | 2 | 125T Puncher machine | Tenzhou (China) | |

| 03 | 5 | 80 T Puncher machine | Tenzhou (China) | 2013 |

| 04 | 15 | 40 T Puncher machine | Tenzhou (China) | 2014 |

| 05 | 5 | Drilling machine | 2015 | |

| 06 | 1 | shearing machine (2500mm) | 2012 |

JINGXIN Advantages

Mold making in House

JINGXIN’s Advanced mold making systems and Mold making in House, Quality control

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

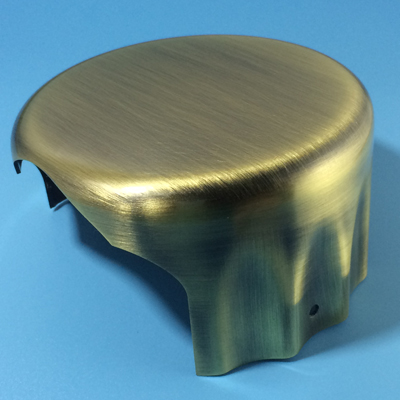

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

Value Added service

Product design, Assembly, Packaging, Programming

High precision

tolerances ranging from +/-0.05mm – 0.1mm, or up on customers’ specs.

Available Materials Listing

| No. | Material |

|---|---|

| 01 | Aluminum |

| 02 | Carbon steel |

| 03 | Stainless steel |

| 04 | Brass |

| 05 | Copper |

| 06 | steel or aluminum Tube |

| 07 | Extruded aluminum |

| 08 | Other special metal |

Available finishes & surface treatment

Choosing the available finishes & surface treatment or other custom finishes are available upon request.

| JINGXIN Advantage & Warranty | |

|---|---|

| 01 | 100+ hours resistance to salt spray |

| 02 | Thin coating |

| 03 | Advanced coating adhesive techniques |

| 04 | Environmentally friendly |

| 05 | JINGXIN’s coating is completely chromium free and RoHS compliant |

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.