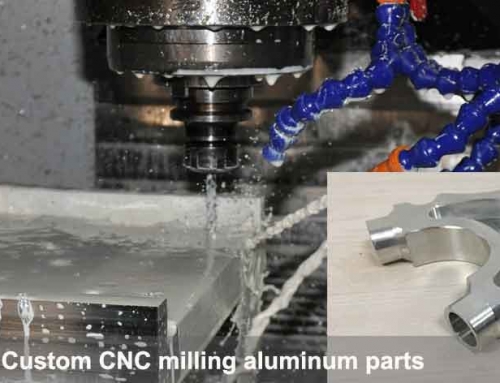

Everyone all know that some high precision components should be processed by cnc machining due to it is top precision manufacturing process among various components processes. However the precision manufacturing process can be divided two types in accordance with products manufacturing phrases,which includes of prototyping and production with CNC machining. Complying with client’s different requirements, professional cnc machining manufacturers provide each respective cnc machining services to response client specific requirements. The following content will have their respective detail description from the two aspects: Prototyping cnc machining and Production cnc machining.

cnc machining for prototyping and mass production

CNC Machining for Prototyping vs. CNC Machining for Production

Before mass production, firstly Components Prototyping should be made, it is an crucial phase in product development, where a preliminary model of a part is created to evaluate its design, functionality, and manufacturability. In this phrase, Components manufacturer request choosing reliable machining tools and process computer control program, proceed an initial components prototyping. Afterwards, components prototyping confirmed , then starting mass production. The two items have a clear difference, let us use a table to explain everyone in detail as the following.

Prototyping With CNC Machining |

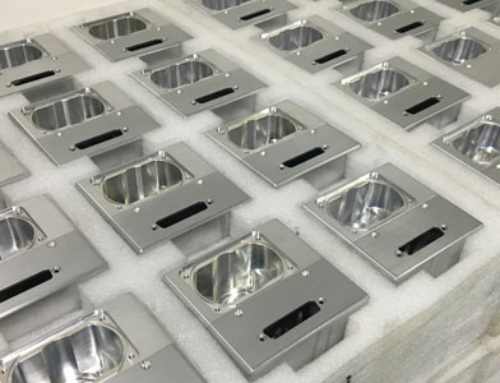

Production With CNC Machining |

|---|---|

Speed and EfficiencyCNC machines can quickly produce prototypes once process computer program is finished, and reducing lead times. Suitable for rapid iterations and precision components samples, allowing designers to refine their models. Material VersatilitySupports a wide range of materials, including metals (aluminum, steel, titanium), plastics (ABS, PEEK, acrylic), and composites. Enables testing of the actual material intended for final production. High PrecisionCNC machining delivers tight tolerances and high-quality surface finishes, ensuring prototypes are accurate representations of the final product. Fit and assembly prototypes to verify part compatibility. Cost-Effective for Low VolumesAvoids the need for expensive tooling, making it economical for single or small-batch prototypes. Functional prototypes for performance testing. |

Custom and Complex PartsIdeal for producing parts with intricate geometries, tight tolerances, and complex features. Short Lead TimesCNC machines can quickly adapt to production schedules, making them suitable for on-demand manufacturing. Quality AssuranceAdvanced CNC machines incorporate monitoring systems to ensure consistent quality throughout the production run. Cost-Effectiveness for Mid-VolumesEliminates tooling costs associated with other methods, making it economical for mid-sized production runs. |