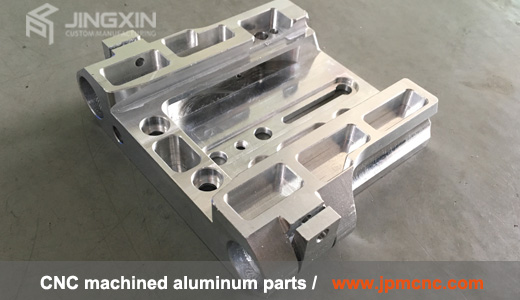

Custom CNC Milling Aluminum components

Custom CNC Milling Aluminum components for motor engine, Custom Sandblast Anodizing and Chemical conversion coating treatment, JINGXIN offers custom CNC milling and turning manufacturing service.with the parts material: metal and Non-metal parts. Fast delivery, competitive cost; ISO factory, JINGXIN® is trusted by VOLVO (Sweden) as a CNC machine workshop in China.At JINGXIN® precision machinery Ltd., offers custom manufacturing services and machined metal parts for Short-run production or 10000+ production. Applications include parts for Auto parts, medical, industry.

*construction equipment components

*oil & gas equipment parts

*High precision safty device components

*Power generation components

*Custom Automotive parts

*House appliance products enclosures

*Medical equipment shell and components

Typical tolerance range from +/- 0.01mm-0.05mm; Welcome to Contact our Project manager(Mr. Sammy Tang: sammy@www.jpmcnc.com) directly for your project.

Custom CNC machining,Custom cnc machined metal parts

Custom CNC Milling Aluminum components

| Project Name | Custom CNC milling aluminum Components for motor engine |

|---|---|

| Application | Automotive, industrial parts |

| Material | 6061, 7075 Aluminum Alloy, Engineering plastic |

| Machinery | CNC Lathe; HAAS 3 Axis Vertical CNC machining center, Wire EDM, Grinding machine |

| Processes | CNC milling, Turning, laser cutting, Grinding |

| Surface treatment & color | Anodizing different color with 72 hours salt spray testing |

| Part Measurement | Customized to the drawing and clients requirement |

| Tolerance required | Without marking DIN 2768-M; Special required at +/-0.01mm |

| Packaging | Carton +wood case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report, Material data sheet & Rohs SGS report, Salt spray testing |

| Client From | Over the world |

Learn more CNC machining services and General purpose material list.

Learn more about JINGXIN Custom CNC Milling and turning services please visit our website click here or talk to our project manager Mr.Sammy Tang for your new project via email sammy@www.jpmcnc.com