Project Description

Precision machining Aerospace parts

Precision machining Aerospace parts, Precision milling service, Precision CNC machining China

JIngxin has over 15 years of experience high Precision machining Aerospace parts,Located Dongguan City China,offer cnc machining services for Aerospace, Defense, Automotive, the automobile industry.

Focus :

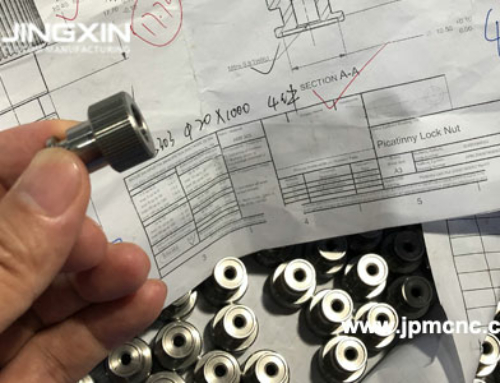

JINGXIN focus on custom manufacturing Non-standard CNC machined parts,high Precision machining Aerospace components such as Fittings, valves, hydraulic components, electric motor parts, transmission and pump parts, sprocket wheels, wear parts on packing machines and electronic and medicinal pieces

Our advantage on high Precision machining part:

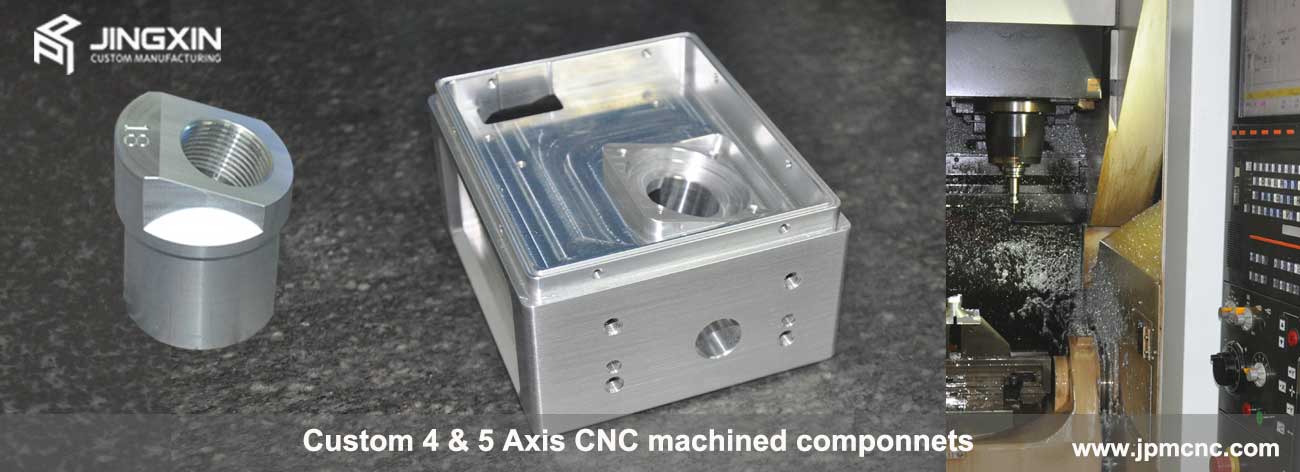

- Advanced equipment: Operate a world-class facility with a variety of precision CNC machines -Brother, HAAS, Mazak; vertical machining centers and precision milling and turning lathes, including 3-; 4- and 5-axis models.

- Complete machining capability in House: ISO 2768-F machining standard tolerance, produce parts in a wide variety of sizes and complexities, Maxi Machining capability up to workpiece size 1000*800*500mm;

- Raw material:100% sure the material complies with Rohs and you required

- ISO factory quality assurance, More details about our testing instruments here

- Order quantity: 1+ order accepted; Short run production and large volume production

- Quicky turn: The quick quote in hours and fast delivery in days. Skilled and professional Team.

For past years, JINGXIN has offered thousands of pieces CNC milled and turned components to our customers. 99.9% satisfaction feedback which drives us to supply more quality precision machined components to meet the demands of Clients.

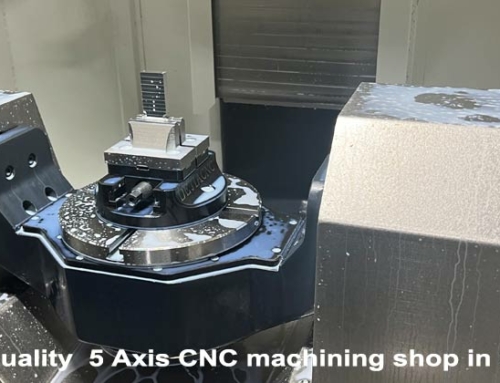

high Precision machining workshop

JINGXIN offer precision CNC machining services in China with world brand CNC machines center, 3-,4-,5- Axis CNC machine center. it allows us to deliver high-quality and on-demand precision CNC machining components like high Precision machining parts, Typical tolerance from +/-0.005 mm to +/-0.01mm for metal parts. Please our whole factory show for more details about precision CNC machining equipment.

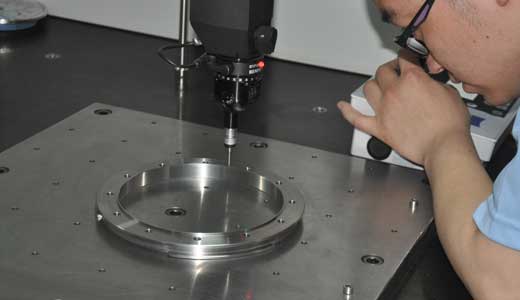

Quality inspection equipments

100% inspection before ship. Every single size would be checked by the related testing instrument. CMM, H.gauge, M. Microscope.etc. Please see our Quality assurance for more details

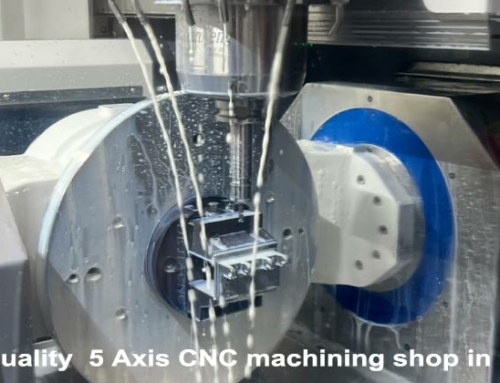

Programing to high Precision machining Aerospace parts

Our skilled Engineer optimizes the tooling path and proposes a best CNC machining process solution and get a result of reasonable cost and high quality of high Precision machining Aerospace parts

high Precision machining processing details

For every single high Precision machining Aerospace parts, Our team including R&D and production departs will work together to finalize the manufacturing process. Best manufacturing solution and optimized tooling path can ensure the quality parts that is our customer required.

finishe treatment Aerospace parts

We can make various Surface treatment and finish as customer requirement for high Precision machining Aerospace parts. Including Anodizing, Black oxide, electroplating,.etc, please see Surface treatment and finish for more details

Fast delivery on time & Rush services

1.1-2 weeks Fast Lead time and 3-5 days Rush services

2. On time delivery by worldwide express UPS, DHL, FedEx, TNT.etc

3. Proper safe packing: Enhanced Carton and wooden case

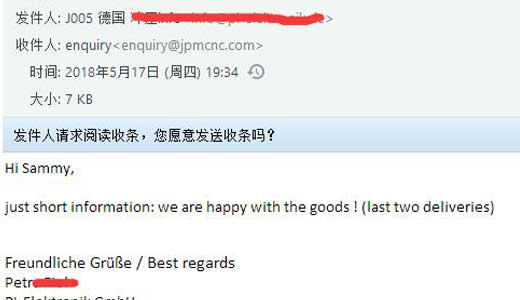

After sale service & customer feedback

JIngxin had a good reputation for manufacturing quality and services: Precision CNC machining, CNC milling and turning. Satisfy feedback are given to JINGXIN among 99.5% Customers over the world

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.