Project Description

Custom machining service – Valve Main Body

Custom machining service

Custom machining service

Custom machining service

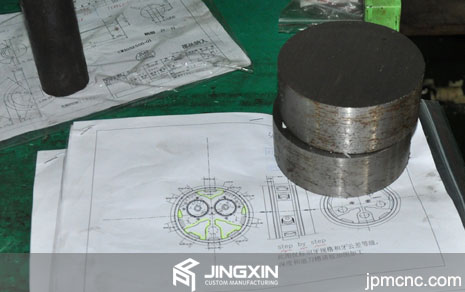

| Project Name | Valves main body |

|---|---|

| Application | Control the flow of fluid in various oil and gas applications |

| Material | SS316 Stainless steel |

| Machinery | CNC turning,4 axis CNC Machine center |

| Processes | CNC turning,cnc milling,taping,WEDM,welding |

| Surface treatment | Polish |

| Part Measurement | DIA 104mm*50H |

| Tolerance required | +/-0.01mm |

| Packaging | Carton +wood case |

| Quality assurance | ISO 9001:2008, ISO 14001 and BS OHSAS 18001 Certification |

| Document supplied | CMM testing report,Material data sheet & Rohs SGS report,Salt spay testing |

| Client From | France |

Custom Machining service processes flow

Preparing Raw material

Our Engineer make a manufacturing plan to valve main body according to the 3D drawing and special requirements,then start to Cutting SS 316 stainless steel rod ,machining the size at 0.5mm bigger than required size.

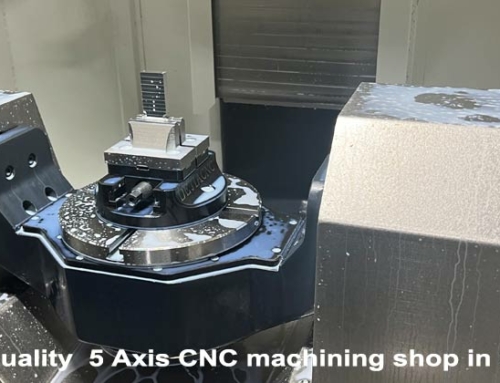

Input G-code Programe

Our skilled Engineers use the software (CAM,UG.etc) to generate the 3D tool-paths and convert into a special programming language called G-code, also optimize the code via suitable tools and tool-paths to produce best quality parts as clients required,then upload to CNC machine.

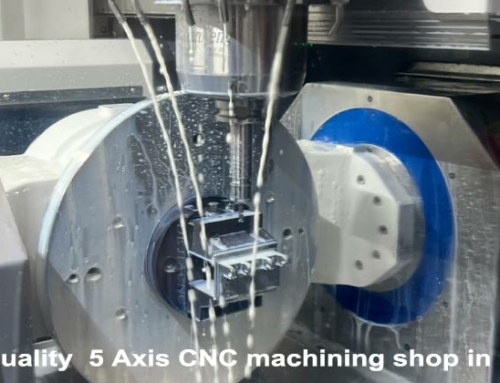

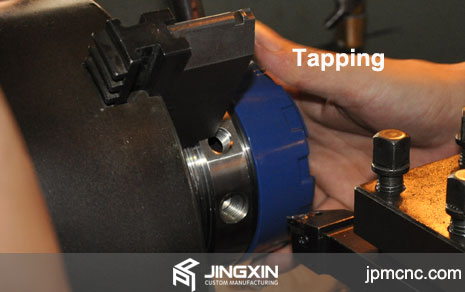

CNC Turning and Tapping

Tapping M95x1.5 thread on both end

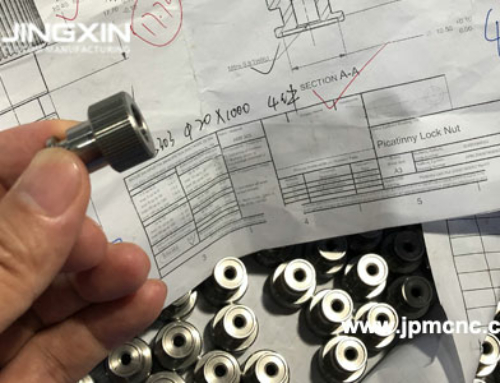

Checking the Thread

Assembly checking the thread to match the thread on aluminum die casting cover.

Wire EDM

In order to Ensure the shape and tolerance inside of valve body , we using slow wire EDM ,tolerance rage at +/-0.01

Final inspection and Assembly

Inspection all dimensions and assemble to ensure all the details are comply with client’s requirements

At JINGXIN®,offers custom machining service, CNC milling, CNC turning,with plastic and metal parts for Short-run production or 10000+ production. Applications include parts for Auto parts, medical, industry. Typical tolerance range from +/- 0.01 mm-0.05 mm; The Fast lead time within 3-6 working days.