Project Description

CNC Milling Services in China

CNC Milling Services in China, High Quality Rapid CNC Milling. CNC mills produce parts of nearly any shape from soft metals like aluminum, harder metals like steel, and plastics such as acetal.

JINGXIN offers cost-effective milling solutions whether you need a single part, batch of prototypes, or full production order.

CNC Milling Services in China high quality

What is CNC Milling?

CNC milling, or computer numerical control milling, is a machining process which employs computerized controls and rotating multi-point cutting tools to progressively remove material from the workpiece and produce a custom-designed part or product. This process is suitable for machining a wide range of materials, such as metal, plastic, glass, and wood, and producing a variety of custom-designed parts and products.

Several capabilities are offered under the umbrella of precision CNC machining services, including mechanical, chemical, electrical, and thermal processes. CNC milling is a mechanical machining process along with drilling, turning, and a variety of other machining processes, meaning that material is removed from the workpiece via mechanical means, such as the actions of the milling machine’s cutting tools.

CNC Milling Machine Parts

Advantages

- Can produce parts of almost any shape

- Cost-effective for prototyping and short runs

- High dimensional tolerances are possible

- Smooth finishes can be achieved

Design Considerations

- Use shapes that will hold well during machining, like straight edges

- Milling creates a visible cut pattern on the surface of the material

- Avoid deep pockets and ensure corners are rounded

- Avoid flimsy shapes

Types Of CNC Mills

3-Axis: The most widely used type of CNC milling machine. The full use of the X, Y, and Z directions makes a 3 Axis CNC mill useful for a wide variety of work.

4-Axis: are more complex because they add the ability to rotate the x-axis, similar to a lathe.

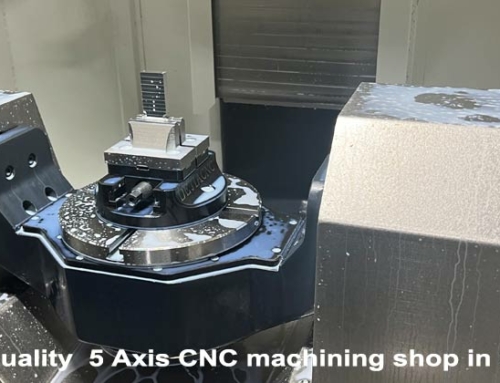

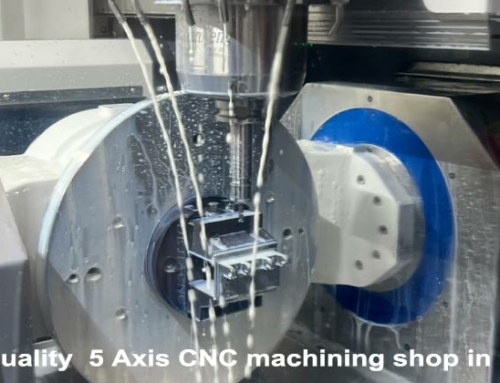

5-Axis: These machines have three traditional axes as well as two additional rotary axes. A 5-axis CNC router is, therefore, able to machine 5 sides of a workpiece at in one machine without having to remove the workpiece and reset. The workpiece rotates, and the spindle head is able to also move around the piece. These are larger and more expensive.

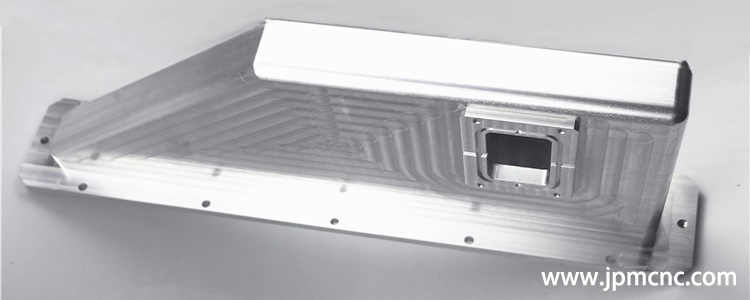

CNC Milling Parts

Professional CNC Machining Manufacturer

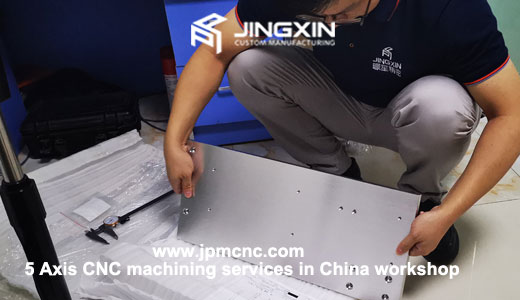

JINGXIN provides excellent CNC machining services for customized precision CNC metal parts. Incorporating the newest CNC machining & milling processes with high standard techniques to satisfied both quantity & quality.

15+ experience:

JINGXIN has over 15 years of experience in custom CNC milling services in China, Located in Dongguan City China. JINGXIN’s Professional team adopt reasonable manufacturing solution and workmanship to supply high-quality one-stop custom CNC machined stainless steel parts.

Focus :

JINGXIN focus on custom Non-standard CNC precision milling services & machined parts such as Fittings, valves, hydraulic components, electric motor parts, transmission and pump parts, sprocket wheels, wear parts on packing machines and electronic and medicinal pieces.

Our advantage:

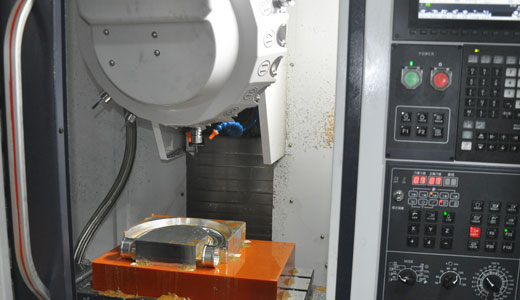

- Advanced equipment: Operate a world-class facility with a variety of precision CNC machines -Brother, HAAS, Mazak; vertical milling centers and precision milling and turning lathes, including 3-; 4- and 5-axis models;

- Complete machining capability in House: ISO 2768-F machining standard tolerance, produced parts in a wide variety of sizes and complexities, Maxi CNC milling capability up to workpiece diameters from 2~350 mm; Learn more JINGXIN’s Capability & Services here;

- Raw material:100% sure the material complies with Rohs and you required, Material certificate and SGS report are available if you need for reference, the Various material: Steel, Aluminum, Stainless steel, Titanium, engineering plastic like PEEK, PC, POM .etc.

- ISO factory quality assurance, More details about our testing instruments for precision milling services here ;

- Order quantity: 1+ order accepted; Short run precision CNC milling & turning and large volume production;

- Quicky turn: The quick quote in hours and fast delivery in days. Skilled and professional Team (R&D); More about us here;

- Our customers are from EU and North American, Learn more CNC machining services Case study.

CNC milling services in chian factory

What we do to make sure you would get the quality parts from JINGXIN precision CNC milling company.

What we have?

Industry Equipments &

CNC milling services in China

At JINGXIN CNC machine shop in China, we supply high precision custom stainless steel parts with world brand CNC machines, CNC turning and milling machine center. it allows us to deliver high-quality and on-demand precision turned components and CNC milled components, Typical tolerance from +/-0.002mm to +/-0.01mm for metal parts. Please our whole factory show for more details about precision CNC milling equipment.

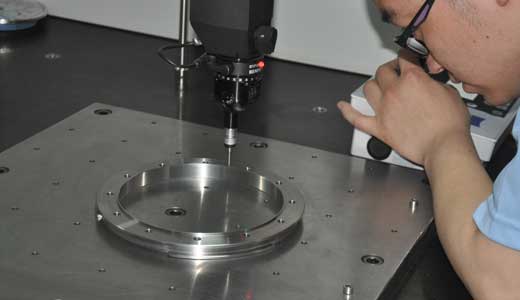

Quality inspection equipments for

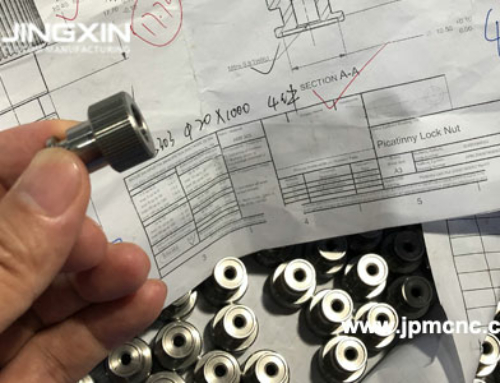

CNC machined Aluminum camera parts

100% inspection before delivery. Every single size would be checked by the related testing instrument. CMM, H.gauge, M. Microscope.etc. Please see our Quality assurance for more details

How do we do for Custom precision CNC milling services?

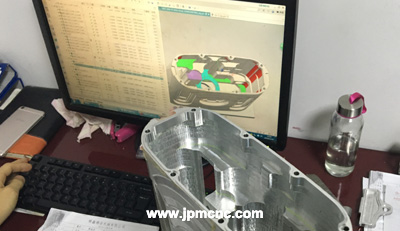

Precision CNC milling services programming

Our skilled Engineer optimizes the tooling path and proposes a best CNC machining process solution according to the design and customer’s request. JINGXIN served worldwide customer for the following parts and so far it is well done: Precision machined 304/316 stainless steel parts, locknut shaft, precision turning aluminum electric motor parts, Precision CNC milling new energy device components, Precision turned aluminum components for electronic and medicinal products.

Precision CNC milling services in china & processing

For every single precision CNC machined parts, Our team including R&D and production departments will work together to finalize the manufacturing workmanship process. Three key factors to ensure the quality: 1. Best manufacturing solution & workmanship; 2. optimized tooling path; 3. PQC during the whole production.so that JINGXIN can ensure the quality parts what is you want from a Precision machined parts supplier in China

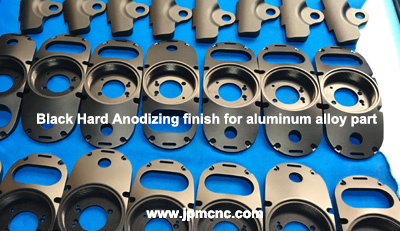

CNC precision milling parts’ finish in house

We can make various Surface treatment and finish as customer requirement for Precision Machining metal or plastic parts. Including Anodizing, Black oxide, electroplating,.etc, please see Surface treatment and finish for more details

Fast delivery on time & Rush services

1. 1-2 weeks Fast Lead time and 3-5 days Rush services,

2. On time delivery by worldwide express UPS, DHL, FedEx, TNT.etc

3. Proper safe packing: Enhanced Carton and wooden case

How long can you get the precision turned parts?

For example: if the order quantity of Precision turned components are below 5000 pcs, then the lead time is 2 weeks, shipping time 2-3 workings days, so you will get the parts less three weeks. also, we supply rush service if you need urgently.

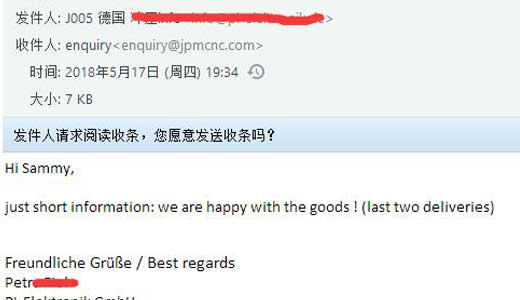

After sale service & customer feedback

JIngxin precision CNC turned components supplier had a good reputation for custom manufacturing quality and services: Precision turned components, CNC milled automotive components such as the wear parts on packing machines. Satisfy feedback are given to JINGXIN among 99.5% Customers over the world, Japan, EU and American market.

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.