Plastic injection molding process and Injection Mold design

When a project manager or engineer designer inquire the injection mold making suppliers about the below questions. What the best kind of plastic can be used for your project? Where is the best parting line on the part surface? How many cavities in an injection mold that can get best parts unit price and reasonable invest in mold cast?

You may get the useful information below for your questions

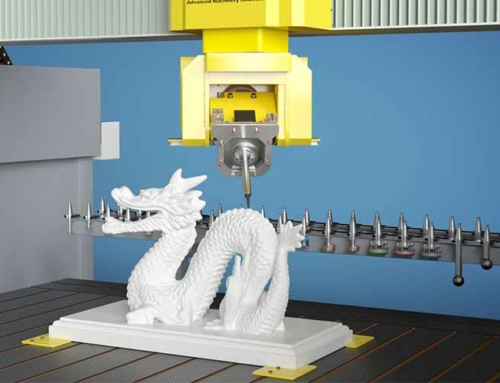

Plastic injection molding process,Injection mould making China factory

1.Plastic injection molding process characteristics

There are many plastic injection molding processes with many kinds of thermoplastic, the thermodynamic properties of plastic shrinkage, mobility, compatibility and hygroscopicity and so are its process characteristics.

*Molding shrinkage

Plastic parts removed from the mold, Cooling shrinkage occurs after the shrinking of the characteristics known as plastic molding shrinkage. Plastic thermal expansion and contraction, mold structure and molding process conditions are all important factors that affect the plastic shrinkage.

*Liquidity

Most of the plastic molding process is the use of plastic in the state of viscous flow deformation and flow achieved. Plastic flow is a measure of the difficulty of plastic forming an anti-index. Good fluidity, plastic melt easily mold filling, access to large-scale thin-walled and complex plastic parts. However, liquidity is too good, there will be flash, plastic physical and mechanical properties of the phenomenon of poor. Liquidity is not good, forming large, thin-walled and complex plastic parts will be filled with dissatisfaction, lack of material. In addition, different forming methods require different fluidity requirements.

General Thermoplastic characters please refer to plastic Physical characters and Application

2.Parting line design on injection molded parts

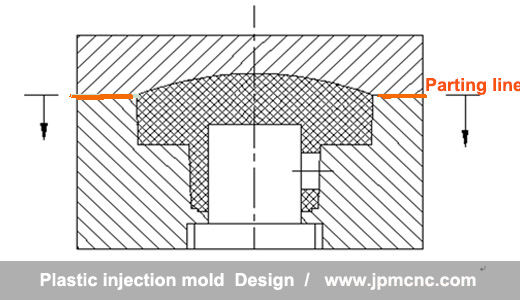

In order to remove the plastic parts from the mold, the mold cavity must be opened. That is, the cavity must be divided into two parts, namely the fixed mold and dynamic mold two parts. Fixed mold and moving surface contact surface called parting line. The parting line can be one or more, of which only one is the main parting line and the other parting line is the auxiliary parting line. The auxiliary parting surface is designed to achieve a certain purpose.

According to the actual design situation the parting line can be divided into flat parting line, inclined parting line, step parting line, curve parting line and vertical parting line.The parting line is an important factor that determines the structure of the mold. While the injection mold parting line is susceptible to mold position, plastic parts dimensional accuracy, the introduction of plastic parts, exhaust and other factors. Therefore, we should pay attention to Comprehensive analysis to achieve a more reasonable design.

5 factors is considered when designing parting line of plastic part

(1) Parting line should be selected at the largest outline of the size of the plastic parts, otherwise, plastic parts will not be able to move the mold off.

(2) The parting line should be conducive to mold release, plastic parts should be left in the movable part. As the introduction of institutions are usually set in the movable mold side. However the core is set in the dynamic part of the plastic cooling shrinkage After the package tight core. The plastic parts remain in the dynamic mode, so favorable demoulding. If the plastic parts of the larger wall thickness, the hole is small or insert, in order to leave plastic parts in the dynamic mode, the general should die is also located in the dynamic mode. When the draft is small or the plastic part is high, in order to facilitate the demoulding, the parting line can be selected in the middle part of the plastic part, but the shape of the part has the mark of the parting type.

(3) the selection of the parting line should be conducive to ensuring the appearance of plastic parts quality and accuracy requirements.

(4) the selection of the parting line should be conducive to the processing and manufacturing of molded parts.

(5) The choice of sub-surface should be conducive to exhaust.

Regardless of the structure of the molded part and the design method used. The parting line must first be determined since the mold structure depends very much on the choice of the parting line. The plastic parting line design, as shown below

3.Design of Cavity

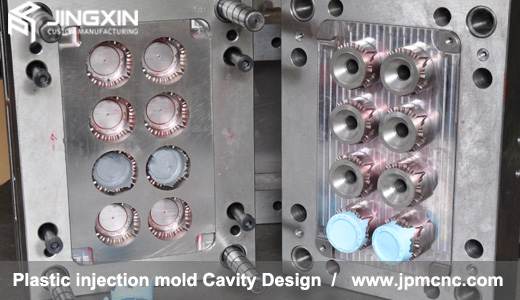

Mold Cavity design

Determination of the number of cavities

In order to mold and injection molding machine to effectively match, improve production efficiency and economy. And to meet the plastic parts dimensional accuracy requirements in the mold design to determine the appropriate number of cavity, there are four commonly used methods.

1) The maximum press of injection molding machine to determine the number of cavities;

2) According to the rated injection molding lock press to determine the number of cavities;

3) The accuracy of plastic parts to determine the number of cavities;

4) Economically determine the number of cavities.

A mold, an injection can only produce plastic parts for the single-cavity mold and can produce multiple plastic parts for the multi-cavity mold. In the case of mass production, multi-cavity mold can increase production efficiency, reduce plastic parts production costs. Multi-cavity mold cavity should be balanced distribution of the cavity plate on both sides. Enabling uniform feeding of the cavity, at the same time full, so molded plastic parts of the same quality and mechanical properties.

At JINGXIN, focus on plastic injection molding and mold making for 10+ years More about JINGXIN please review our website www.jpmcnc.com.

For further more information about the Plastic injection molding process and manufacturing. Please contact JINGXIN engineer to give you some advice and help you finish your project on time. Or read more about our plastic injection molding case study.