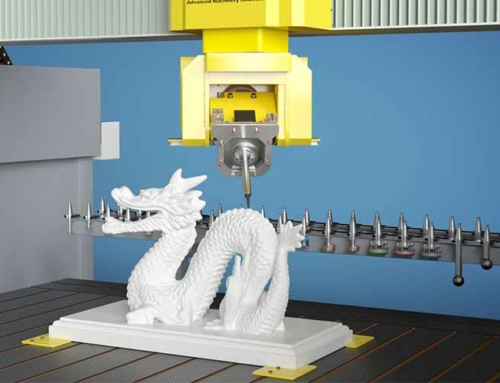

Custom manufacturing workflow for CNC machined components

Custom manufacturing workflow,First of all, As a sales manager at JINGXIN custom manufacturer, We always get an FAQ from our new customer about how is about your quality and what you will do to ensure the quality we need? Yes, sure, it is key focus point that is cared about for every oversea purchasing manager or designer, Therefore,

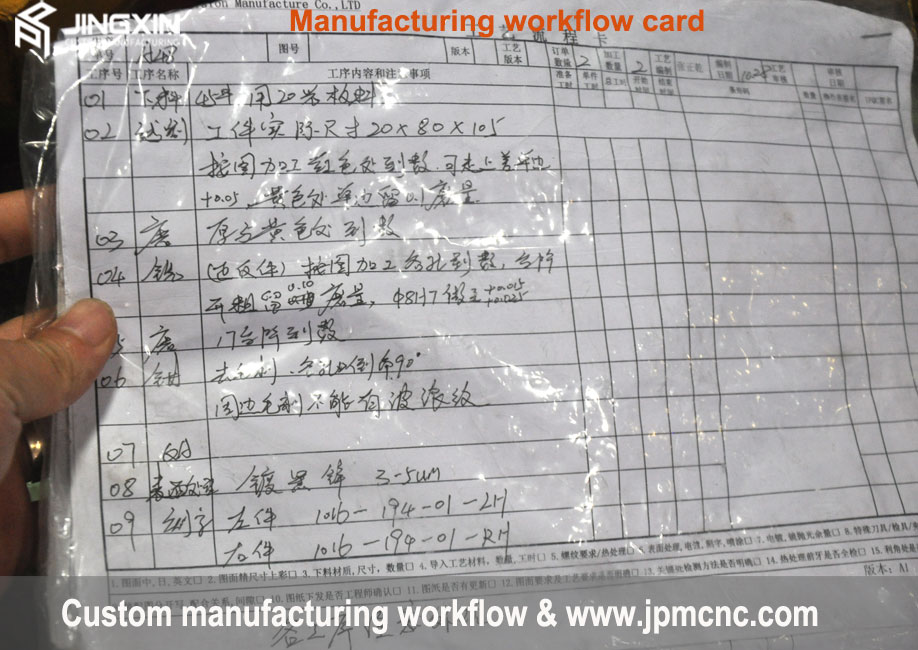

In this article, I’d like to highlight the manufacturing workflow in our JINGXIN custom CNC machining services. What is it, Why is it important and what should you pay attention to? What is its benefit for quality control and as a result in customers’ satisfy? Obviously, I have to point out every part is a little different and every shop has a little bit different workflow.

What is CNC machining manufacturing workflow?

CNC machining manufacturing workflow is a documentation of manufacturing process and methods. it is used to guide the production and especially relevant to the standard quality control management. It is in the specific conditions of production as well the most reasonable machining process for the machined parts.

Why is manufacturing workflow important for CNC machining production?

Manufacturing Workflow is important because it can guide people how to machined the specified parts and help QC staff tracing the quality along with the production, From purchasing the Raw material to end of packaging and delivery.

For many of experienced machinist who work at home-owned-workshop, Maybe they just make the parts according to their experience and had a workflow in their mind or write down some note on drawing paper. But for a big factory like JINGIXN that there are many machinists who just take charge of one or two steps in the workflow. Therefore, The manufacturing workflow is a necessary guidance to make sure the parts machined in order as clients requirements and no any mistakes.

What should you pay attention to the workflow?

At the beginning, when we get an order or custom CNC machined metal or non-metal parts. We need to study and have an overview of all the features of the CNC machined parts and related requirements on 2D drawing, then make a reasonable manufacturing workflow. If you do a CNC machining parts manufacturing workflow, you maybe take the following three key points for your reference, Whatever you do, but at JINGXIN, our machinists did as following:

*First, you write down machining process steps, Using less machining steps to finish the parts to save the Cost,

*Next, Thinking about the right machining process steps to ensure the tolerance and quality

*Finally, Share the workflow with your R&D team and machinists to double check if it is the best one based on the current machining equipment station.

Examples of manufacturing workflow please refer to below JINGXIN’S CNC machining manufacturing workflow.

Custom manufacturing workflow for CNC machined components

What is its benefit for quality control and as a result in customers’ satisfy?

In our view, the manufacturing workflow will function as a guide for quality staff to check the parts accuracy after finishing every machining step. Meanwhile, the manufacturing workflow will be a belt that makes all machinist in a line to finish the job. Therefore The quality requirements and custom specification of parts will be ensured as well the customer receives the right parts.

As you can see, how is the manufacturing workflow important for manufacturer even especially for a customer & buyer who start working with a new Chinese CNC machining factory. The more reasonable manufacturing workflow, the more benefit buyer will get, competitive cost, good quality and on time delivery

Read more tips about Custom CNC machining services

Learn more Case study at JINGXIN

IF you have a custom machined component to do, welcome to contact us (email:enquiry@jpmcnc.com) for a project review and instant quote.