How to make a plastic prototype? there are three main options you can choose from:

How to make a plastic prototype? there are three main options you can choose from:

Make it by yourself (DIY), 3D printing online and hiring a professional prototyping manufacturer. Which one is the best for you depends on project design, your budget and time? However, For the easy prototype, you can make it by yourself to use paper material or wood by simple tooling,

regarding another complex project, it is better to hire a professional prototyping company to make it. the professional rapid prototyping manufacturing will help your work out your design and create a professional prototype and finally give you some valuable insight suggestion to your product like material, surface finish treatment then help to improve your product design that almost close to mass production.

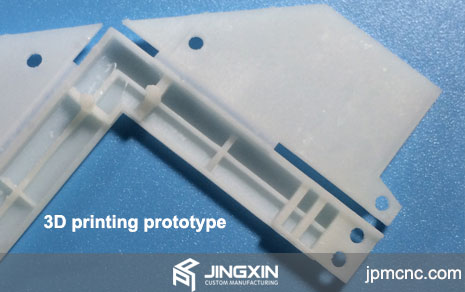

3D Printing online

What is 3d printing prototype? 3D printing is the fast and easy way to bring your design into reality to see how is your design. It is a kind of additive manufacturing with plastic like material. Nowadays 3D printing became more affordable as a viable option for creating a rapid prototype. The 3d printing prototype is the cheapest methods comparing with others process like CNC milling, CNC turning, Vacuum casting.

3D printing can create a more durable, functional prototype out of materials similar to what their finished product would be made from. Common materials available for 3D printing include plastic and metal.

3D printing can create a more durable, functional prototype out of materials similar to what their finished product would be made from. Common materials available for 3D printing include plastic and metal.

You need to provide 3d CAD file better stl or stp format, so you might need to learn how to create a CAD model or you find a company like that will create it for you according to your draft, concept of product you would like to create a rapid prototype.

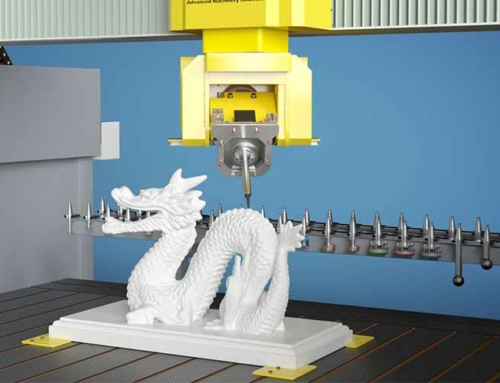

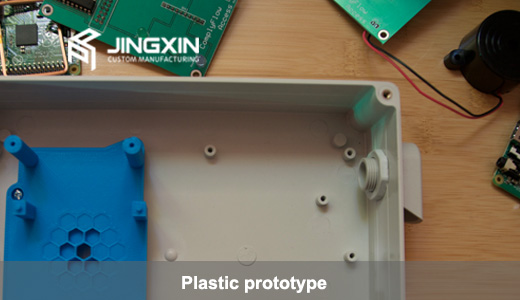

Professional prototyping Company

If you are working for a company as a designer and need a plastic prototype for final checking before mass production, the best solution is to work with a professional rapid prototyping factory like JINGXIN precision machinery Limited that provides one-stop service of rapid prototyping and short-run production in China. Working With a professional prototyping company, it means that you will get the benefit from a team of experienced engineers and machinists who will give you some suggestions to create a quality prototype and some good comments of the fabrication process for mass production. Also, Surely you will get a prototype that is almost the same as mass-manufactured products.

A professionally manufactured prototype is great for exhibiting at trade shows to give your clients a complete idea of the new product. Low-cost and short-time consuming to Working with a professional services company. From start to finish within 1-2 weeks, if you use the other methods like plastic injection molding then you must wait 4-6 weeks to receive your prototype. So having a professionally made prototype is very important before moving your project to mass production.

A professionally manufactured prototype is great for exhibiting at trade shows to give your clients a complete idea of the new product. Low-cost and short-time consuming to Working with a professional services company. From start to finish within 1-2 weeks, if you use the other methods like plastic injection molding then you must wait 4-6 weeks to receive your prototype. So having a professionally made prototype is very important before moving your project to mass production.

For more information about plastic prototype method, contact us