How does a CNC machine operate

How does a CNC machine operate? A CNC, CNC machining or computer numerical control machine is a high precision tool that’s computer-controlled and makes repeated, accurate movements. It does so by taking the computer-generated code and converting it with software to electrical signals. The signals are what control the CNC motors and directs them to move in small increments that are highly precise and repetitive.

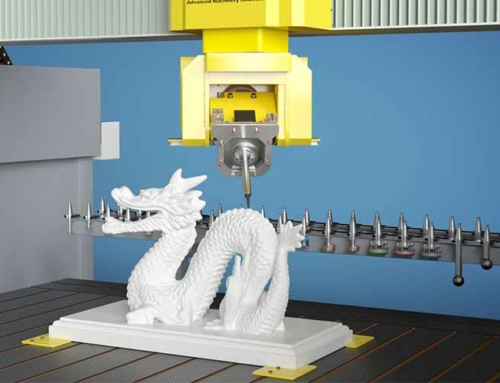

CNC machines can do almost anything you need them to do, also call CNC machining services. So customizable in nature, a lot of manufacturing industries & CNC machining services factory use these machines to create parts. These industries can afford the large price tag that comes along with the convenient custom capabilities. An example of parts made via CNC is here

Tips Below is the CNC machining advantage VS traditional manufacturing

CNC machining VS Traditional

| Advantage | CNC machining | VS | Traditional manufacturing |

| Lead times | Fast | Slow | |

| Production efficiency | High | Low | |

| 3D complex parts | multi Axis CNC machining | simple parts | |

| Operation Control | Computer Numerical Control | Depends on skilled machinist | |

| Surface | high, smooth and bur free | N/A | |

| Quality assurance | One stop site for Tiny or large parts with complex design | one type equipment Only for a single process |

CNC Machine is Controlled by Different Systems

CNC Machine is Controlled by Different Systems

To get a CNC machine to work properly, there needs to be a dictated software control to get the desired results from a computer design. The two most popular software packages used are Mach3 for Windows and EMC2 for Linux. Once the part design is drawn, it is converted to G-Code, which is what controls the CNC. This CAM (computer aided manufacturing) program can be the most difficult part, and a lot of industries choose Vectric Software as their go-to. Note that the CAM doesn’t actually run the machine, though it creates the code for the machine to follow.

In addition, some machines have their own programming language and a specific CAM is required to create NC code for the machine to understand. In these cases it can require a postprocessor that serves to bridge that gap in communication. The postprocessor usually makes it possible to use any machine and translate anything to the needed code for a specific machine and part.

Conclusion

The above is how CNC machines work or called cnc machining services, and this applies to large-scale machines, as well as hobby-size machines. In the manufacturing industry, these machines are usually a CNC mill, CNC lathe, CNC router, CNC laser cutter, CNC grinder, CNC sheet metal bending or a robot for plastic injection molding and an assembly line.

A CNC machine can also work based on the number of axes it has to offer. If cutting on the same plane, a two axis is usable as it can’t move in the vertical plane. A 2.5 axis machine is for when cutting takes place in the parallel planes of the principal plane but not always at the same depth or height. If simultaneous, controlled movement of the X, Y, and Z axes is necessary, a 3 axis is good choice. Like the 3 axis, the 4 axis variation adds in one rotary axis movement for repositioning or interpolation. The 5 axis machine is the same but with two rotary axis movements, so five axes are moving simultaneously in the machining process.

More on CNC machining service here.

If you need CNC machining service for your project, Welcome to Contact our Project manager(Mr. Sammy : enquiry@jpmcnc.com) directly for your project.