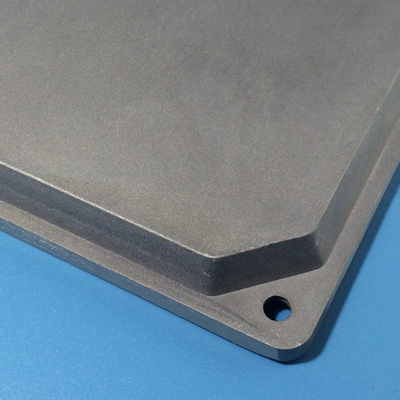

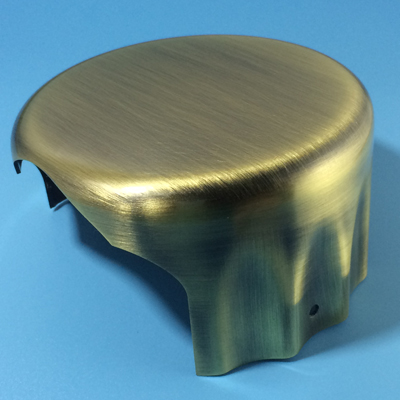

Finishing & surface treatment can be used for protection, decoration, and other uses. For example to your custom machining services parts, you may want to make electroplating or other post-treatment on your custom machined parts to protect it from oxidizing or mechanically brush the surface of the part to create a textured look. At JINGXIN® precision machinery Ltd., offers Various post-treatments & surface finish such as oil painting, powder coating, soft touch painting, Teflon & PVC coating, electroplating, aluminum anodizing, silk screen printing, laser engraving, Hardness treatment, wiredrawing, etc..or up to customer requirements.

Finishing & surface treatment can be used for protection, decoration, and other uses. For example to your custom machining services parts, you may want to make electroplating or other post-treatment on your custom machined parts to protect it from oxidizing or mechanically brush the surface of the part to create a textured look. At JINGXIN® precision machinery Ltd., offers Various post-treatments & surface finish such as oil painting, powder coating, soft touch painting, Teflon & PVC coating, electroplating, aluminum anodizing, silk screen printing, laser engraving, Hardness treatment, wiredrawing, etc..or up to customer requirements.

To guide you to make sure the finish you specify is compatible with your material. Welcome to Contact our Project manager(Mr. Sammy: sammy@jpmcnc.com) directly for your project

Jingxin Features

- 100+ hours resistance to salt spray

- Thin coating

- Advanced coating adhesive techniques

- Environmentally friendly

- JINGXIN’s coating is completely chromium free and RoHS compliant

- custom machining services & manufacturing services

Available finishes & surface treatment

The surface finish for the metal parts we can provide with are as the following:

A) Blacking, zinc plating, chrome plating and nickel plating for the Carbon steel and the low alloy steel parts;

B) Tumbling, hand dull polishing, mirror polishing, electrolytic polishing and passivation treatment for Stainless steel parts;

C) Sandblasting(including glass bead blasting, corundum-sand blasting, and quartz-sand blasting), polishing and anodizing for Aluminum parts.

D) Read more Top 10 Surface Finishing For Metal Parts

| Finishes | Making | Finishes | Making |

|---|---|---|---|

| Polishing & surface grinding | In house | ElectroPlating | Contacted suppliers |

| Sandblasting & Bead blasting | In house | Anodizing | Contacted suppliers |

| Painting | In house | Flame/ Vacuum/Nitrided hardness | Contacted suppliers |

| Screen printing for mark | In house | Hot Galvanized | Contacted suppliers |

| Laser engraving | In house | Chemical Black & Black Oxide | Contacted suppliers |

| Powder coating | In house | Vacuum plating | Contacted suppliers |

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.