CNC Machining is suitable for various material’s precision manufacturing process, In accordance with different functional parts, cnc machining manufacturer can select appropriate material to do a detail process, and ensuring meeting the requirements of applications in various industries. Different material, we can adopt different process method to process them. In structure of the material, They include three types : Metals,Plastics and Composites. The follow information will focus on introduction of common materials used in cnc machining, which contains the main 3 types material.

1. Metals

We will list some common material for cnc machining precision, they are often used on the mechanical chassis, fittings, Aerospace components ,automotive components, medical surgical equipment, communication device housing, Decorative trim and Consumer Electric etc.

CNC Machining Metal Components

Aluminum

Common Grades: 6061, 7075, 2024. The material is used widely for Aerospace, automotive, electronics, medical devices. It advantages is lightweight, corrosion-resistant, easy to machine, good strength-to-weight ratio.

Steel

It includes: Carbon steel (1018, 1045), Alloy steel (4140, 4340), Stainless steel (304, 316, 17-4 PH) These steel material can be used to Structural components, tools, automotive, medical devices. Particularly Stainless steel components are mostly used in surgical instruments. It have these advantages that high strength, durability, corrosion resistance (stainless steel), hardness.

Brass

Grades: C360, C260. The material is easy to be processed, it can be made to Valves, fittings, electrical components, Its strong points are Excellent machinability, corrosion resistance, electrical conductivity, aesthetics.

Copper

The material is processed into Electrical components, heat exchangers, plumbing. It’s advantages have high thermal and electrical conductivity, corrosion resistance.

Titanium

Grades: Grade 2, Grade 5 (Ti-6Al-4V), The material is often used for Aerospace, medical implants, high-performance automotive parts due to its high strength-to-weight ratio, corrosion resistance, biocompatibility.

Magnesium

The material is used in Automotive, aerospace, electronics enclosures. its advantages are lightweight, good machinability, high strength-to-weight ratio.

Zinc

Zinc is newly alloy material, Zinc die casting process can make decorative components, automotive parts, sensor housing and electric consumer goods. its advantages are excellent machinability, corrosion resistance, wear resistance.

2. Plastics

Plastic material contains the below common materials, at some specific conditions, they can be processed by cnc machining into some individual components for particular applications. These materials are listed in detail.

China Rapid prototyping,Rapid manufacturing,Short run & low volume production

Acrylic (PMMA)

Light covers, displays, lenses and decorative boxes are made of acrylic material. Because it is transparency, lightweight and shatter resistance.

Polycarbonate (PC)

Machine guards, automotive components and smart device covers are made from PC material.

Advantages: Impact resistance, optical clarity, durability.

Nylon (PA)

Some of Gears, bearings, bushings are made from Nylon material. The material is high wear resistance, low friction, toughness.

Delrin (POM)

Applications: Gears, fasteners, bearings may be made from POM material. the material has advantages of high strength, rigidity, low friction.

ABS

Prototypes, housings, automotive components require the material of ABS. Its features are impact resistance, machinability and low cost.

PTFE (Teflon)

Seals, gaskets, chemical-resistant components, these parts may be made from PTFE. They request these features of chemical resistance, low friction and temperature stability.

HDPE (High-Density Polyethylene)

Containers, wear strips, piping were durable,and made from high-density polyethylene material. Obvious characteristic is lightweight, impact resistance and corrosion resistance.

3. Composites

cnc machining composite material

Carbon Fiber-Reinforced Polymer (CFRP)

Some specific components may be used in Aerospace, automotive, sporting goods.

Its Advantages: High strength-to-weight ratio, stiffness, corrosion resistance.

Glass Fiber-Reinforced Polymer (GFRP)

Some particular components in Aerospace, marine, smart wear. Its characteristic is high strength, impact resistance and low weight.

Epoxy Composites

Applications: Electronics, aerospace, tooling

Advantages: Good thermal stability, chemical resistance, structural strength.

Phenolic Resins

Electrical insulators, heat shields.

Its advantages: High heat resistance, electrical insulation.

Bakelite

Electrical components, insulators may be made of bakelite. these components need high electrical resistance, and thermal resistance.

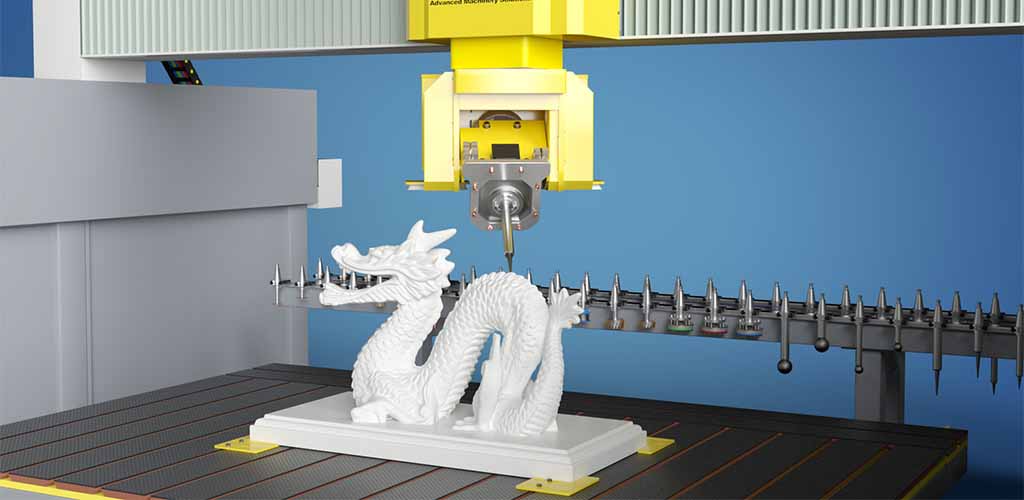

4. Stone, Ceramic And Glass

cnc machining carving stone

These material gifts,crafts and decorative parts come into our life and environment. They will be processed precisely into some exquisite jewelry, pendents and decorative parts by cnc machining. This is an extension industry of cnc machining process. Craft workman can use cnc precision machining to replace their traditional processing , either enhancing process effective or saving more labor cost. However, the industry will request more skilled-well operators to finish those complex and intricate craft process in the future. Automation cnc machining process will gradually be instance for traditional craft process.