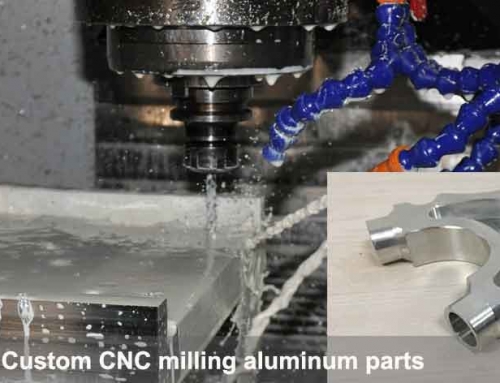

CNC machining process has become a popular approach for CNC Machining parts in Electronics and Communication due to the high precision, versatility, design flexibility and high productive rate offered by CNC technology. With the innovation of automation and digital technology, CNC machining process will become more and more intricate and complex, its toolpaths will implement cutting movements from multi-angles visual, aim to process some top notch components for Internet of things equipment and Electronic consumer goods. CNC Machining parts in Electronics and Communication is more suitable for the trendy of artificial intelligence technology development. The below we list advantages and applications of cnc machined parts in electronics and communication fields.

Advantages Of CNC Machining Processes Electronics and Communication Parts

1. Precision and Accuracy

CNC machines can achieve tolerances as tight as ±0.001 mm, critical for intricate designs. The process is operated by numerical program, the cutting routers can be executed in precision and accuracy. Eliminate manual errors actions and products defect rate. Meanwhile automation process avoids some human body hurt in accident.

2. Material Versatility

Common Materials Used in CNC Machining include aluminum, zinc alloys, copper, plastics, and stainless steel. These material can be processed into various shapes components, which are used widely in many industries, such as automotive, aerospace, communication, electronic consumer goods and construction decoration industries etc. Manufacturers can choose different material to produce components in accordance with the requirements of functionality and applications the components.

3. More Smoother Surface Finishes

CNC machining can make excellent surface finishes due to tight tolerance precision and accuracy.The process makes the surface of parts even smooth areas and less roughness. They can be directly power coated, anodized, or plated for aesthetic and functional purposes, without any polishing and secondary post-process.

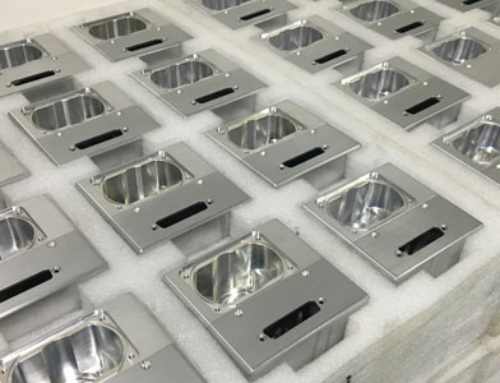

4. Customization Become More Easier

Being easy and convenient for prototypes and low-volume production where design changes are frequent, flexible. Engineers can design part process with CAD software, and convert drawn CAD files into G-code that process program is implemented in CAM system. Customization part design is realized though modify CAD files, and become more easier for customization.

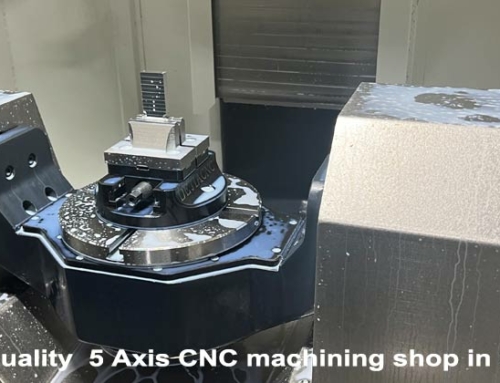

5. Complex Designs

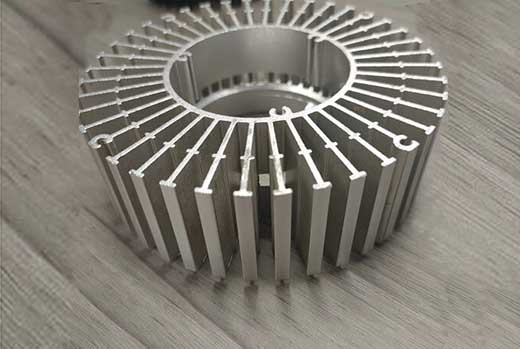

Capable of producing intricate shapes for housings, connectors, heat sinks, and antennas. Complex designs is done on the desktop only, any time complex design changes can be done, and make its complex designs more convenient and portable. By a small size of usb flash drive disk, The cnc machining can gain the flexible design and execute accurate and precision processing.

Main CNC machined Parts in Electronic and Communication

| Main Application Scope | Detail Description |

|---|---|

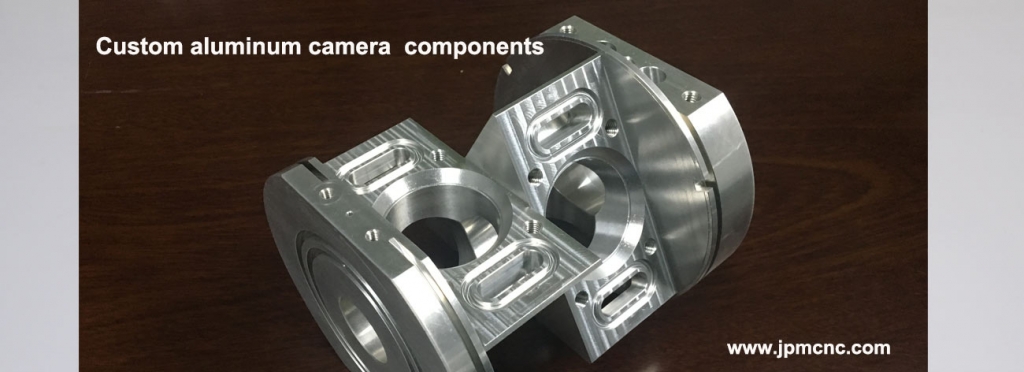

| Housings and Enclosures | Protect sensitive electronic components from environmental conditions and electromagnetic interference (EMI). Such as CCD camera housing. |

| Heat Sinks | Efficiently dissipate heat from high-performance electronic devices. like thermal conductivity aluminum heat sink for hard disk. |

| Connectors | Precision-fit parts for signal transmission in communication devices. they have a good electricity conductivity, which are made from zinc alloy, aluminum and copper material. |

| Antenna Components | High-frequency parts used in wireless communication devices. They are durable and strong corrosion resistance, and endures harsh weather and moisture environment. |

| PCBs and Substrates | Machined from high-performance plastics or ceramics. its characteristic is insulation, wear resistance and high temperature -proof. |

| Fasteners and Clips | Provide assembly and stability within communication systems. Some miniature metal components, which used to fix and connect electric components together. |