The Solutions to improve the quality of CNC machined parts

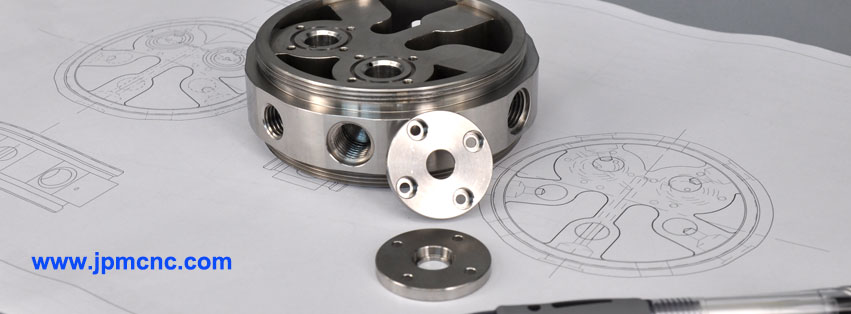

There are many factors that affect the quality of CNC machined components or parts. The machines and tools accuracy and parts structure design are two important factors. This article focuses on the analysis of the CNC machines and tools accuracy effect to the quality of CNC machined parts. This Proposal from JINGxin precision machinery limited, a professional CNC machining manufacturer in China.

When machining a work-piece on a CNC machine, there are many factors that affect the quality of the machining. If a defect is found in the work-piece, First step to check the cause of the work-piece. Something likes clamping method, the tool used, the cutting amount, and the processing method. When these reasons are eliminated, the second step to check the accuracy of the machine to find the reason. The accuracy of the machine is an important factor affecting the quality of the part. Once the accuracy of the machine tool is poor, some parts are damaged. Or the clearances of various parts are not properly adjusted, the work-piece will cause various defects during processing.

Therefore, we must not only reasonably select the turning angle, cutting amount, and machining method. But also understand the influence of machine tool accuracy on the machining quality in order to master the methods of adjusting the machine tool and eliminating defects. In order to make the parts structure have a good mechanical processing and less cost, the parts should be designed and improved. It is based on the feedback from the manufacturer. The machining process and which kind of CNC machines used.

Effect of Machine Accuracy on Machining Quality

The shape accuracy and position accuracy of the parts mainly depend on the precision of the machine tool itself. Including the accuracy of the spindle rotation, the accuracy of the bed rails, and the accuracy of the tool rails.

Spindle Rotation Accuracy

The rotation accuracy of the spindle directly affects the work-piece geometry (including roundness, face flatness, etc.) errors, dimensional errors, and surface roughness. Each surface of the spindle supports the surface accuracy of the journal, the mounting gear, and the chuck. Usually, the radial round run-out and the end surface run-out of the spindle shaft and other related rotary shaft diameters and shoulders are measured. According to the precision requirements of the machine tool, it is controlled within a certain numerical range. For the radial run-out of the front and rear bearing journals installed on the main shaft, generally, about one-third of the processed parts are allowed.

Bed rail guide accuracy

The bed rail surface is a reference surface for measuring the geometrical accuracy of the machine tool and reflecting the machining accuracy. This reference plane shall ensure the linear accuracy of the slide motion both. When it is unloaded or when it is subjected to cutting loads so that the tool can obtain even and smooth straight-line feeds. At the same time. Other relevant motions and related installation surfaces should be guaranteed. Slide motion maintains mutual position accuracy.

After the surface of each guideway is worn out, the precision of the straightness error caused by the movement of the carriage in the horizontal plane. This has the greatest influence on the machining accuracy when finishing the long shaft parts. Each use unit can specify the machine tool according to different machining diameter, length and accuracy requirements. The extreme wear value, and according to the process requirements of different parts, combined with the technical conditions of the machine tool to determine the availability of the machine tool. As a basis for major repairs.

Methods to Adjust The Accuracy Of The machining Tool

1 Re-correct the mounting position of the spindle axis of the spindle head so that the work-piece is within the tolerance range.

2 Use the adjusting horn to re-align the bed rail’s tilt accuracy and tighten the anchor bolts.

3 Scrape the guide rails to ensure horizontal guide rails.

4 Adjust the lateral screws on both sides of the tailstock to ensure that the spindle is concentric with the centerline of the tailstock.

Measures to Improve the parts Machining process

In order to make the structure of the part have a good mechanical processing technology, to ensure the quality of the work-piece processing. In addition to the reasonable dimensioning and the specified processing accuracy when designing the part. The following issues should also be considered:

Simplify the structure of the parts and reduce the machining surface

The structure of the parts should be as simple as possible to ensure the use of the parts, so as to facilitate processing and reduce the amount of processing. Save material and save time.

Conducive to Larger Cutting Amounts When designing parts

It is necessary to consider that the parts have sufficient rigidity and appropriate structure. This makes a larger amount of cutting can be used during processing to reduce maneuvering time and increase processing efficiency.

Reasonable facilitate tool to enter and exit

To facilitate the tool to enter and exit the machined surface of the part should ensure that the tool can reach, so that the processing surface is in the processing position. In order to make the tool free to exit during processing, there must be an undercut groove in the work-piece. The design should be drilled When the box parts are used. The distance between the drilling position and the box wall should be kept from being too small and the box wall should be too high. Otherwise, the standard length drill bit cannot be approached by the drilled surface.

Using Standard tooling

Use of standardized tooling to reduce the number of types of tools. The holes to be drilled in the part shall have a standard diameter so that a standard diameter drill bit can be used. When there is a non-through hole or a hole with a diameter transition to another diameter. The whole bottom and The transition should be designed to have the same conical surface as the drill tip. If the groove is machined with an end mill, the radius of the outer fillet should be designed to be equal to the radius of the standard end mill. Making standard tooling can be used to avoid designing a right-angled groove.

Facilitate the installation

To facilitate the installation and reduce the number of parts designed for installation. The blank should be able to be installed on the machine tool and reduce the number of work-piece installations. This can reduce or avoid the positioning error caused by multiple installations of the work-piece. Which is beneficial to improve The accuracy of the mutual position between the surfaces of the work-piece is reduced. And the auxiliary time required for loading and unloading the work-piece can be reduced, and the productivity can be improved.

Avoid machining the inner surface

To avoid machining the inner surface of the unopened inner surface and an inclined surface, the shape and size of the tool will be limited by the space in the inner space of the work-piece. At the same time, it is difficult to operate the tool and measure, and the inner surface is not opened. It is more difficult and should be avoided. When machining inclined surfaces, it is often necessary to reposition the work-piece or turn the tool.

When designing, it is necessary to reduce the slope as much as possible to reduce the number of mountings and simplify the fixture structure. For drilling, the axis of the hole should be perpendicular to the upper and lower end faces. This will avoid drilling holes in the slope or curved surface, so as to avoid biasing the drill bit or breaking the drill bit.

Conclusion

The quality of the CNC milling parts or CNC turned components are affected by the accuracy of the machine equipment. The accuracy of the machine equipment is affected by the manufacturing, daily maintenance, and the correct use of the operator. Therefore, according to the failure of the machine in use and the defects that often occur in the processing of the work-piece, repairs should be made in time.

In order to ensure the accuracy of machines and the quality requirements of the machined components. Meanwhile, the process designer at JINGXIN precision machinery limited always fully consider the structural and mechanical properties of machining. Which can not only improve the quality of the product, but also greatly improve the labor productivity of product processing, shorten the time of machining.

With those solutions and good conditions of machines, JINGXIN supply the high-quality custom CNC machining services over the world. Therefore, JINGXIN was trusted by Volvo automotive company and another customer from Japan, EU.etc. IF you have customized parts need to make, please contact us for a project review and competitive quote for reference.