Can stainless steel be CNC machined?

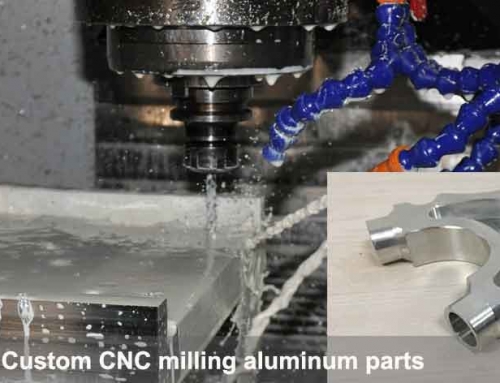

Yes, stainless steel can be CNC machined. CNC (Computer Numerical Control) machining is a process used to remove material from a workpiece using computer-controlled tools. Stainless steel is a common material used in CNC machining due to its durability, corrosion resistance, and strength. However, it can be more challenging to machine compared to some other materials due to its hardness, which may require specialized tooling and machining techniques.

can stainless steel be cnc machined

Why is stainless steel a good material for so many different applications?

JINGXIN offer CNC machined service, we work with difference kind of raw material , including stainless steel , Aluminum alloy, engineering plastic POM , PEEK, PTEF..etc.

Absolutely! Stainless steel is widely used in various medical applications due to its excellent properties. Its corrosion resistance, strength, and ease of sterilization makes it an ideal choice for medical instruments, surgical implants (such as joint replacements, screws, and plates), medical devices, surgical tools and equipment used in healthcare settings. Additionally, certain grades of stainless steel are biocompatible, meaning they are well-tolerated by the human body, making them suitable for prolonged medical implantation.

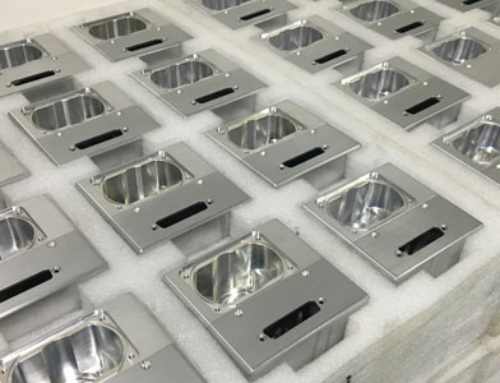

precision machining service

How do you design a part for machining?

1. Material selection: Choose the right grade of stainless steel suitable for the specific application. Even though considering factors like corrosion resistance, strength, temperature resistance, and compatibility with the environment or chemicals it will be exposed to.

2. Design geometry: Consider the part’s shape, size, and complexity. Simplify the design where possible to reduce manufacturing complexity and cost. Avoid sharp corners and edges that might increase stress concentrations.

3. Tolerances and fits: Specify appropriate tolerances and fits to ensure the part functions correctly and interfaces properly with other components in the assembly.

4. Machinability and manufacturing processes: Stainless steel can be challenging to machine due to its hardness. By Considering of the machining techniques, tooling, and processes needed for the specific stainless steel grade to achieve the desired part geometry.

5. Surface finish: Determine the required surface finish based on the application’s requirements. In some cases, stainless steel parts might need specific finishes for aesthetics, corrosion resistance, or functional purposes.

6. Mechanical properties: Understand the mechanical properties required for the part’s function, such as strength, ductility, and toughness. Choose the stainless steel grade that meets these mechanical requirements.

7. Corrosion resistance: Ensure the selected stainless steel grade has the appropriate corrosion resistance for the intended environment or exposure to chemicals or bodily fluids in medical applications.

8. Biocompatibility (for medical applications): The stainless steel part will be used in medical devices or implants. This ensures the chosen grade is biocompatible and meets relevant standards for implantable materials.

By considering these factors during the design phase. You can optimize the performance, manufacturability, and functionality of stainless steel parts for various applications.