What is injection moulding?

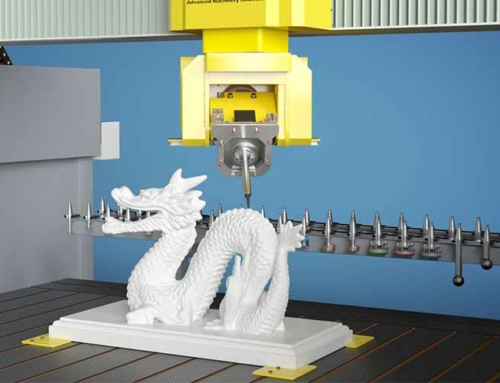

What is injection moulding? Plastic injection molding is a manufacturing process for producing parts by Feeding the thermoplastic Material into a heated barrel, mixed, and forced into a mould cavity via injection machine. it is a popular and economical industrial process for manufacturing consumer products with various kinds of material such as ABS,PC,PP,.etc.

Injection moulding process

Insert Molding

Over Molding

Multicolor molding

Internal/external thread molding

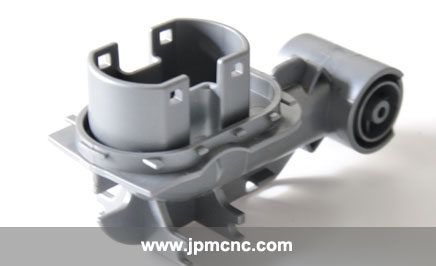

Applications

plastic injection moulding is to produce plastic products including from the smallest components to entire body panels of cars, such as house hold appliance, electronic products enclosures, Medical, gears, power tools, bottle, kids toys, computer monitors, furniture and so on.

Equipments -Injection Machine

There are two kinds or injection machine for plastic injection molding, The majority of injection machines are horizontally oriented, other one is vertical injection machines who is specially used for insert molding with the advantage of putting in and taking out of the insert from the cavity, such as power plug, screw driver.etc. These two kind of machine with different mold design from fastening mold on plastic injection machines.

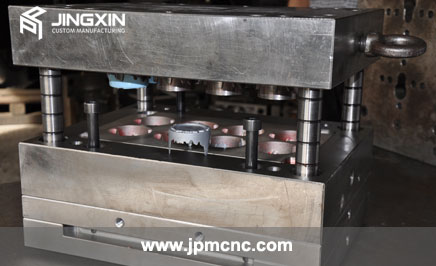

Tooling -Injection mold

In the plastic molding process, we need a professional mold factory like JINGXIN factory to make injection mold from metal according to the parts design. Parts to be injection moulded must be very carefully designed to facilitate the moulding process. Learn more how to make a mold please refere to injection molding.

Popular thermoplastic Material for injection molding

ABS,PC,PP,PS,POM,PMMA,PVC,PA.

For more about plastic injection molding services please contact us, we will try our best to help you on your project.