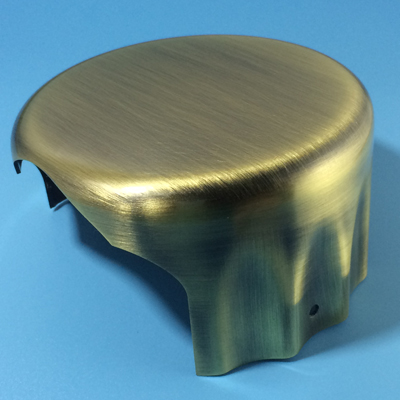

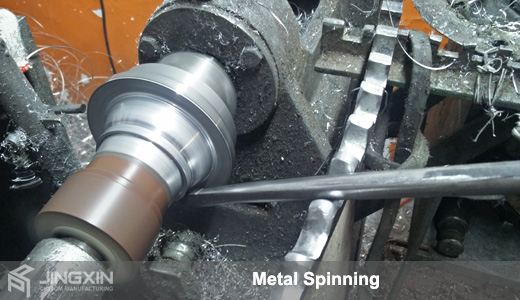

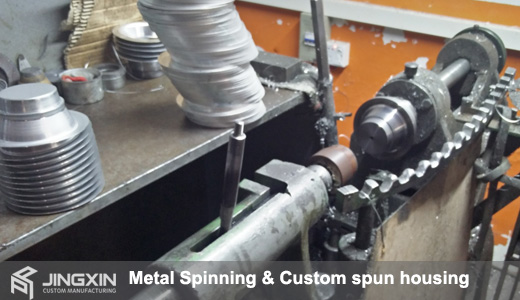

Metal Spinning & Custom Metal Spun Housings

At JINGXIN® precision machinery Ltd., offers metal spining, Metal stamping, Deep drawn stamping, and Forming services with many kinds of metal material for Short-run production or 10000+ production.

At JINGXIN® precision machinery Ltd., offers metal spining, Metal stamping, Deep drawn stamping, and Forming services with many kinds of metal material for Short-run production or 10000+ production.

Our spinning process services work with many kinds material including aluminum, Hastelloy, Inconel, stainless steel,. Utilizing both CNC and manual equipment allows us to spin materials as thick as 0.5~5mm and as large as 500mm in diameter. Tolerances range well within ±.2mm and will meet the most stringent customer requirements.We serve many industries: home appliance, lighting fixture, automotive, electronic.etc

Welcome to Contact our Project manager(Mr. Sammy : sammy@jpmcnc.com) directly for your project.

JINGXIN Advantages

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Mold making in House

JINGXIN’s Advanced mold making systems and Mold making in House, Quality control

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

High precision

tolerances ranging from +/-0.05mm – 0.1mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

Our Capabilities

| Items | capabilities |

|---|---|

| Services | Full range of service: Metal spinning, metal stamping, deep drawn stamping, and forming service |

| We focus on | Auto parts, Medical, lighting fixture, Home appliance |

| Production volume | Short Run or 10000+ production, and high volume production |

| Maximum parts size | 500mm in Diameter |

| Material thickness ranges | from 0.2mm to 5mm |

| Typical tolerance range | from +/- 0.1mm-0.2mm |

| Tooling lead time | 20-25 working days |

Available Materials Listing

| No. | Material |

|---|---|

| 01 | Aluminum |

| 02 | Carbon steel |

| 03 | Stainless steel |

| 05 | Copper |

Available finishes & surface treatment

Choosing the available finishes & surface treatment or other custom finishes are available upon request.

JINGXIN Advantage

- 100+ hours resistance to salt spray

- Thin coating

- Advanced coating adhesive techniques

- Environmentally friendly

- JINGXIN’s coating is completely chromium free and RoHS compliant

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.