CNC Turning services

CNC turning services

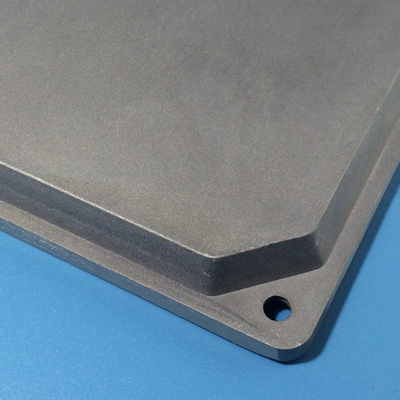

CNC turning process adopts computer numerical control program to machine round shape parts, it works with many materials plastic or metal. The advantage of CNC Turning process is the high consistent quality in terms of tolerance and smooth surface compared with traditional manual turning machines.

At JINGXIN® precision machinery Ltd., offers CNC milling service with a variety of demands with plastic and metal parts. Applications include parts for Auto parts, medical, industry. Typical tolerance range from +/- 0.01mm-0.05mm; Part size up to 400mm Diameter.

Welcome to Contact our Project manager(Mr. Sammy : sammy@jpmcnc.com) directly for your project.

Our Advantages

Quick turn & Service

Quick feedback in 24 hours.Case by case followed via One-on-one service.

Fast Lead time

JINGXIN skilled machinists produce high-quality parts as little as 3-6 working days

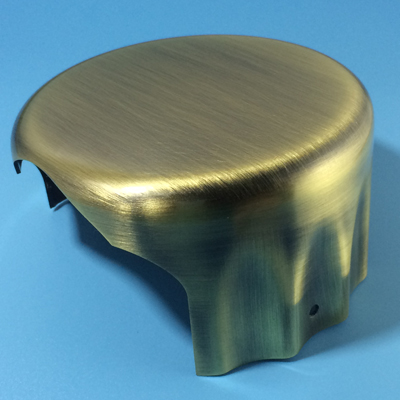

Custom finishes

Select from a variety of finishes and surface treatment or up on request.

High precision

tolerances ranging from +/-0.01mm – 0.05mm, or up on customers’ specs.

Value Added service

Product design, Assembly, Packaging, Programming

Our CNC machining capabilities

A Full Range of Services

| Milling | Turning |

|---|---|

| High speed drilling | Tapping |

| Boring | Slotting |

| Reaming | Rotary Broaching |

Value Added Services

| Lasing cutting service | Laser Marking |

|---|---|

| Laser Engraving | Welding & Forming |

| Debrring | Assembly & Packaging |

| Product design & assistance | Progamming |

CNC Turn center (live tools) and Maximum machining size

| No. | Model | Brand | sets | Maximum machining parts size | Year |

|---|---|---|---|---|---|

| 01 | CNC lath | Baoji(Taiwan) | 10 | 400mm Diameter | 2015 |

Available Materials Listing

General Purpose material for CNC machining ,Raw material forms can be sheet/bar stick/tubing/plate

Plastics

| No. | Material |

|---|---|

| 01 | ABS |

| 02 | PC (Polycarbonate) |

| 03 | Delrin |

| 04 | PEEK |

| 05 | POM |

| 06 | PMMA (Acrylic) |

| 07 | Bakelite |

| 08 | PVC |

| 09 | Teflon |

| 10 | Other special plastic |

Metals

| No. | Type | Grade |

|---|---|---|

| 01 | Aluminum Alloy | 5052 /6061/ 6063 / 2017 / 7075 ,.etc. |

| 02 | Brass&Copper | 3602 / H59 / H62 / C3600/C38500/,.etc. |

| 03 | Stainless steel | SS 301,SS304,SS316,SS400,SS430,etc |

| 04 | Carbon Steel | A2,Q235,20#,45#.etc |

| 05 | Titanium Alloy | |

| 06 | Magnesium alloy | |

| 07 | Zinc alloy | |

| 08 | Tungsten Carbide | YG8,YG10 |

| 09 | Titanium alloy | |

| 10 | Other | Up on Customer’s requests |

Available finishes & surface treatment

JINGXIN Features

♦100+ hours resistance to salt spray

♦Thin coating

♦Advanced coating adhesive techniques

♦Environmentally friendly

♦JINGXIN’s coating is completely chromium free and RoHS compliant

Project Service Guide

-

Enquiry

Design Source Files(STL、STP etc); Order Quantity; Tolerance Range; Surface Treatment Requirements; Purpose

-

Project Review & Quote

Sign NDA(non-disclose-aggrement) if need. Project Review By Engineers Follow Up Project all details; Make Quotation for client

-

Biz Terms

Shipping method & documents; Term of Payment; Packaging Details; Delivery Date,etc.

-

Project Execution

Production Plan; Workflow & Process Control; Monitoring in whole procedure. Feedback to Client continually.

-

100% QA before Shipping

All Functions Testing; Surface Testing; Go Through All Project Details; Packing Testing; Testing & QA Report.

JingXin is the ideal supplier of Custom CNC machining services & manufacturing !

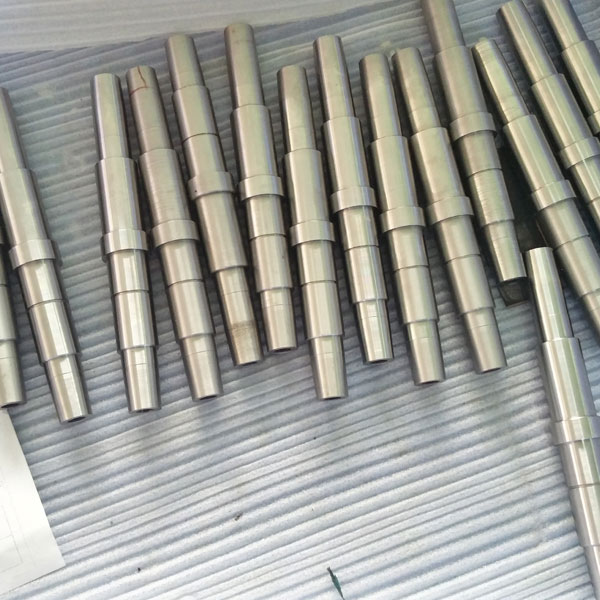

Precision CNC Turned stainless steel valve body

Precision CNC Turning stainless steel pipes connectors

CNC turned Volvo’s Auto shaft parts