Aerodynamics proof that turbine can bring more wind energy and dynamic power under machines and aircraft are running in fast speed. These strong aerospace aircraft and spaceships request more advanced turbine engines to speed up.The demand of these complex turbine blades will create a blue sea for cnc machining industry, meanwhile large challenges and difficulties come to us. To match with the demand of the technology innovation and development, we introduced 5-axis cnc machining equipment and precision inspection and testing instruments from some developed countries to produce complex and integrated turbine blades to fill this piece of strong potential market. Meanwhile, I as one professional cnc designing engineer, also have a detailed introduction for 5-axis cnc machining and its benefits to everyone.

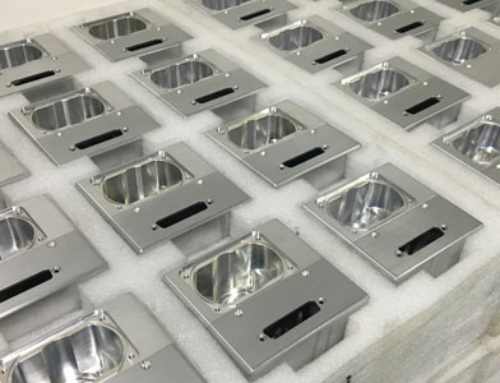

precision cnc machining process equipment

What is 5-Axis CNC Machining?

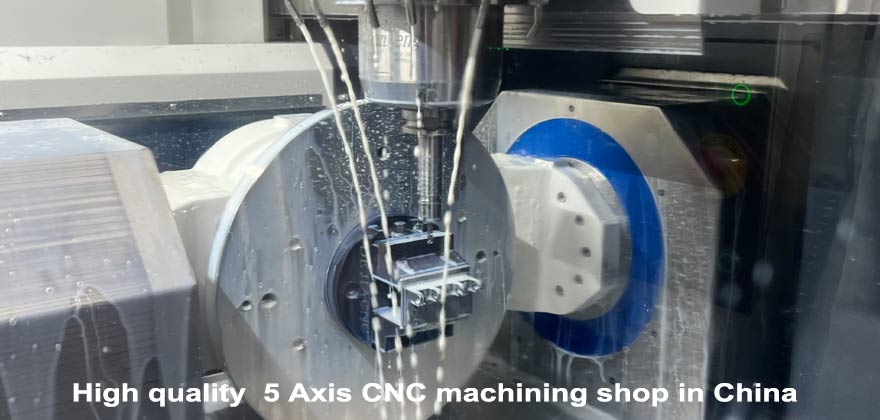

5-axis CNC machining is an advanced manufacturing process, which using a cutting tool to process some complex and intricate part from turning, milling, boring and drilling at one stop in one cnc machining center only . Compare to 3-axis machining, which operates on three linear axes (X, Y, and Z), 5-axis machining adds two additional rotational axes (A and B). This enhanced capability makes the machine to approach the part from virtually any angle. Because added two rotational axes, Its process programming edits become more complex accordingly. It need to make perfection CAD files with advanced Design software, and then imported to CAM software system installed on the advanced cnc machining center, executes complex moving toolpaths to process some intricate structural automotive engine parts, aerospace components and human bodies bone shapes in medical surgical research fields. It belongs to best top notch of cnc machining process.

How 5-Axis CNC Machining Works

In 5-axis cnc machining process, Except for the part or cutting tool rotates around X and Y axes, accordingly produces additional rotational axes(A and B), Add common Z axis which moves up and down and control the depth of process. This build 5 axes cnc machining. The five axes typically include:

- X-Axis: Horizontal movement (left to right).

- Y-Axis: Horizontal movement (front to back).

- Z-Axis: Vertical movement (up and down).

- A-Axis: Rotation around the X-axis.

- B-Axis: Rotation around the Y-axis.

The integration of these axes allows for simultaneous movements, and making it can process more intricate and complex workpieces in limited space. Even though some abstract structural components. But also its intricate movement track can save more process cost. So the advanced cnc machining process is resulting in greater flexibility, precision, and efficiency.

5 axis milling turbine blades

Benefits of 5-Axis CNC Machining

When we encounter some intricate structural components from some of specific clients, we may not achieve an ideal solution to process the part with traditional cnc machine centers. However 5-axis cnc machining equipment will process it smoothly. It brings multi-benefits to us. Listed it as the follow.

1. Enhanced Geometric Contour and Structure Flexibility

It can finish smoothly complex and intricate design components, including aerospace components, medical devices, and automotive parts. Especially dynamic power turbine blades and automotive engine core components production. Reduces the need for multiple setups, allowing the machining of complex geometries in a single run. Only added further process program in computer control.

2. Improved Accuracy and Precision

Eliminates manual repositioning, reducing cumulative errors. But requests more proficient technician and program editors. Achieves superior precision for high-performance parts, which meeting multi-functions and complex structural components in aerospace, automotive and robotic equipment production fields.

3. Reduced Lead Times

Its simultaneous movements streamline machining processes. The advanced cnc machining process needs more professional operators to finish components process. Once the process program is set up, the production of the part will be finished quickly. It can complete parts faster by eliminating intermediate steps. All process steps can be finished in one set of equipment, reducing shift machine operation times. Its work is high efficient.

4. Superior Surface Finish and more smoother contour

The advanced machining Allows the cutting tool to maintain a consistent angle, improving surface quality. It can have multi-angle optimal, makes the contour and shape of machined components more even an smoother. Minimizes the need for secondary finishing processes due to its multi-axis movement cutting and making the surface of components even areas.

5. Cost-Effectiveness for Complex Components

Reduces reliance on custom fixtures and jigs. it can finish the whole process of the part once, and only a set custom fixture and clamping tooling. The 5-axis machine is integrated cnc machining process, a complex component can be processed by one machine only, without two and over two machines in steps.

6. Wide Material Compatibility

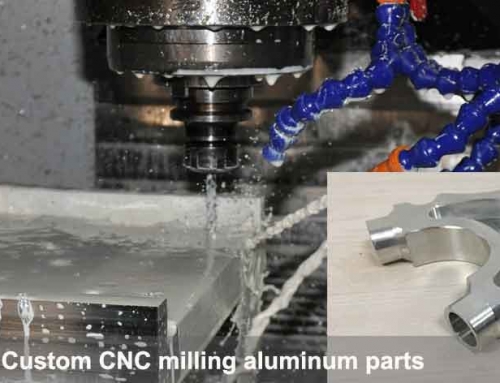

Handles a broad range of materials, including aluminum, titanium, stainless steel, plastics, and composites. By using 5-axis cnc machining equipment, depending on the detailed requirements of client, and adopting reasonable cutting tools to process high precision practical components and aesthetic appearance high grade goods.

Applications of 5-Axis CNC Machining

Aerospace

Turbine blades, structural components, and engine parts that require complex geometries and tight tolerances. These specific components can be utilized on key places in the machines and air crafts to improve their performance and dynamic power.

Medical

Surgical implants, orthopedic devices, and medical instruments requiring intricate designs and biocompatible materials. To meeting the above requirements, we adopt 5-axis cnc machining to produce some imitated bone parts on human being body and other through tube with some biocompatible material.

Automotive

High-performance engine components, molds, and custom parts for advanced vehicles. When automotive engineers are focus on the study of fuel-efficiency engine on automobiles, they found that many components can be made by 5-axis cnc machining. These precision components are intricate and integrated.

Energy

5-Axis CNC Machining enables Precision components for renewable energy systems, turbines, and power generation equipment. Some functional components and key components can improve performance of machines and dynamic power. The complex and precise contour and structure of these components should be produced by 5-axis cnc machining.

Tool and Die

Complex molds and dies for manufacturing processes like injection molding and metal stamping. Especially undercut of mold and die and the plastic injecting mold of deep textures of specific shaped decorative artworks which need precision and accurate dimensions to achieve products with high quality.

Conclusion

In summary, view of my opinion, 5-axis CNC machining represents the pinnacle of precision manufacturing. It offers unmatched capabilities for producing complex and high-quality components. Its benefits—including enhanced geometric flexibility, superior accuracy, and faster lead times. The unique process is an indispensable tool across industries like aerospace, medical, automotive, and energy. Leveraging this technology can drive innovation and efficiency, We will explore deeply technology fields such as aerospace dynamic power and automotive fuel- efficiency engine fields.