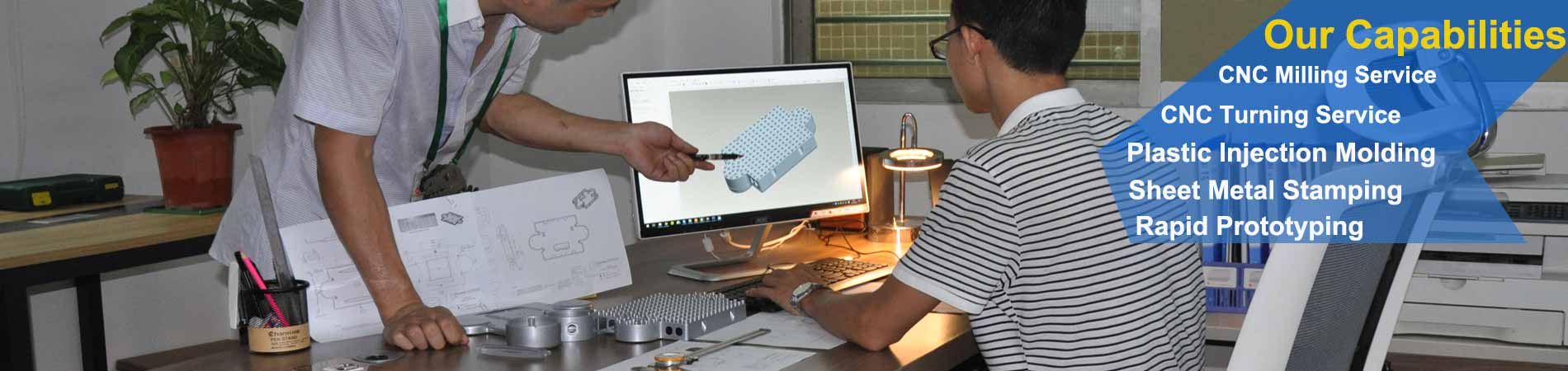

One-stop Custom Precision Machining Services on demand in China

JINGXIN® provides a full range of Custom Precision machining services such as Rapid prototyping, CNC machining services, and Metal Stamping,Over 20 years, the passion & responsibility drive us to do more in quality assurance and service optimization.

Pro engineers+Services Team

20+ service team consisting of experienced engineers and well-trained sales Engineer. Quote in 24 hours

Quality Assurance & Control

100% inspection before delivery, 99.5% Qualification Target, Full monitoring all the time.

Custom Precision Machining Services

We focus on Custom precision machining services including Custom CNC machining, Thermal plastic injection molding, Sheet metal fabrication, Custom finishing In-House etc. We work with you every step of the way, from initial project review and quotation to inspection and delivery.

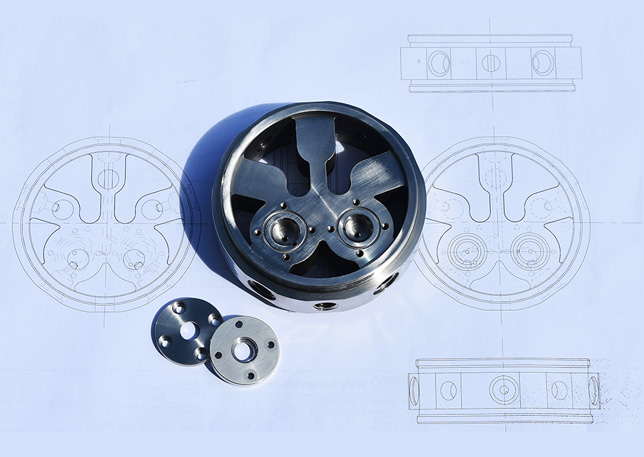

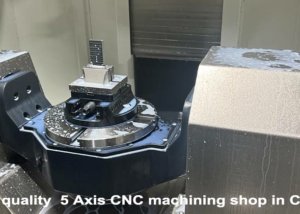

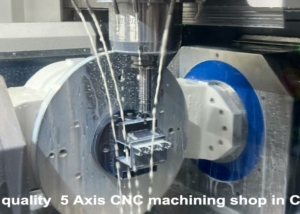

CNC machining services

Precision machining services including CNC milling, CNC turning, wire EDM, Surface grinding, etc. Using our imported 3, 4 and 5-axis HAAS CNC machining centers, our skilled machinists can make turned and milled parts with a wide range of plastic and metal materials.

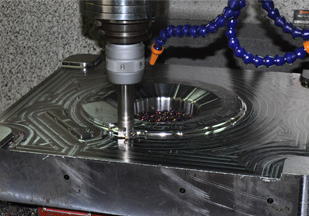

CNC MILLING

CNC milling is commonly applying a machined surface finish on plastic or metal or for creating complex 3D shapes. We use domestic and imported 3, 4 and 5-axis CNC machining centers with live tooling to supply precision machining services for our customers.

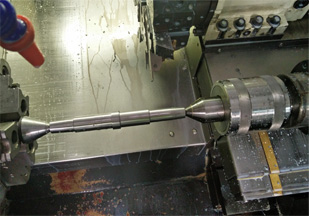

CNC TURNING

Our CNC lathes enable high speed and quality turning of both plastics and metals. The turning process allows for complex external geometries and internal bores generated. Our turning capacity is up to dia 400 mm with quantity 1-10000+ per month.

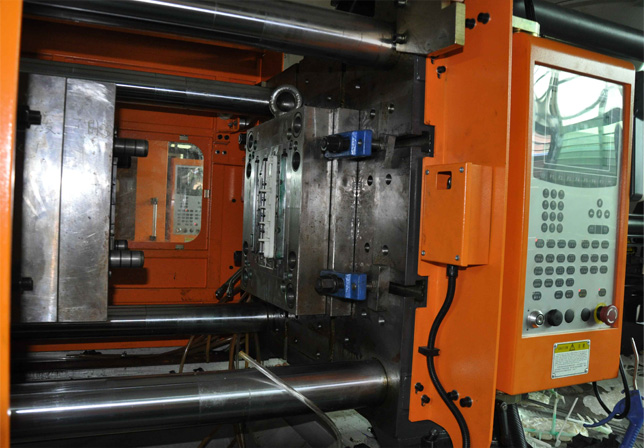

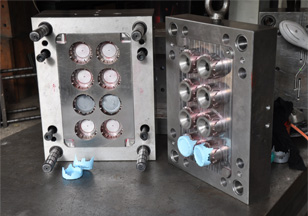

MOLD & MOLDING

We specialize in high-quality custom plastic injection molding and mold tool making. Plastic injection molding is by far the industry’s most common way to manufacture plastic parts, especially when making larger quantities.

PLASTIC INJECTION MOLDING

When producing plastic parts, a variety of polymers are available including thermoforming plastics, thermosets, and some elastomers. Mold tools and the plastic injection molding process are both carefully engineered to match the unique requirements of each material.

EXPORT MOLD

When making your mold & tooling we use pre-hardened tool steels such as P20, NAK-80, and S136,etc. The material used will depend on your specifications, the type of resin and the number of parts you want to produce.

SHEET METAL FABRICATION

We have high speed, state of the art metal fabrication equipment that is best suited for repetitive, low-to-high volume and high-mix production runs. As a complete tool and die shop, we are skilled in all areas of fabrication including fiber laser, CNC punching, CNC bending, CNC forming, welding, CNC machining, and assembly. Many of our processes are automatic, such as the material handling on our two 5000-watt fiber lasers, allowing us to run minimally attended or even lights out. We can handle any portion of your project from laser cutting flat blanks to providing you with a full assembly ready to ship to your customer. Our on-time delivery average is 95%.

- (2) 5000-watt fiber lasers with material handling automation, 60 x 120″ max sheet

- CNC Punching: 20-ton capacity. Max. sheet size 48″ x 96″. Material thickness range .006″ to .25″

- CNC Brakes: Up to 300-ton capacity and 14 feet of bending

- MIG, TIG & Spot Welding

- Managing painting, plating or other subcontracted services

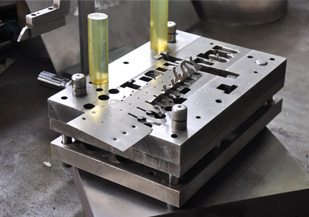

METAL STAMPING

precision, short-run stamping process utilizes a unique tooling method where hardened tooling components are used in conjunction with standard holders and fixtures, thereby taking the place of conventional die sets.

DEEP DRAWING

Deep drawing is the stretching of sheet metal stock, commonly referred to as a blank, around a plug. applications are typically enclosures, cans, cups, canisters, containers, cover, motor shrouds, tanks, shells, etc.

SPINNING

We can spin parts up to 36 inches between centers. Our machinery can handle a material thickness of up to 0.250 of an inch for stainless steel, 0.375 of an inch for carbon steel, and 0.750 of an inch in aluminum to create parts that measure up to 100 inches in diameter.

CNC BENDING

CNC bending is a process where sheet metal is bent to an angle using, typically a V shaped punch and die. The sheet is placed between the punch and die which presses down on the sheet into 2D or 3D shapes.

We provide High-quality Rapid prototype and Low-volume production services with rapid tooling or other rapid manufacturing processes. Our international team of engineers has combined advanced manufacturing technologies like 5 Axis CNC machines with traditional manufacturing techniques to provide you with a One-stop shop for all your manufacturing needs.

Rapid Prototyping & Rapid Manufacturing

- Show your customers and investors a model of your product

- Demonstrate the appearance, dimensions, and features of your product

- Test your design for its suitability

- Save time and money by identifying and reducing design flaws

- Improve and streamline the production process

- Reduce your work load when the time comes to manufacture

- Create multiple versions with different colors, surface textures, and finishing processes

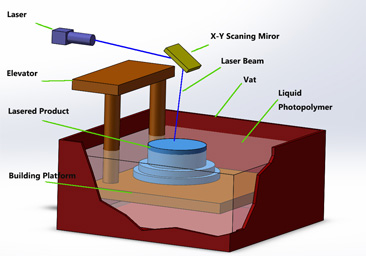

SLA/SLS 3D PRINTING

SLA & SLS are 2 common kinds of 3D printing processes methods. Good for making rapid, one-off plastic prototypes. You can create complex internal structures that can’t be made by traditional plastic manufacturing.

VACUUM CASTING

Vacuum casting is a method of silicone rubber mold suitable for producing max to 30 prototypes.We select Many materials type,and also can combine 2+ different types of material in a single finished vacuum casting.

CNC RAPID PROTOTYPING

CNC Rapid Prototype is ideal for making plastic or metal prototypes, these prototypes are same as products made parts. Also CNC can reduce tolerances with better surface finishes than other prototyping methods.

DIE CASTING

Die casting is a metal casting process that forcing molten metal under high pressure into a mold cavity. The mold cavity created using two hardened tool steel dies which have been machined into shape that similarly to injection mold.